Stroll round any facility, campus, or store flooring, and you’ll quickly see a acquainted rhythm: technicians shifting between areas, retrieving elements, reviewing work orders, navigating entry, and then lastly engaged on belongings and gear. That essential “on-tools” window, wrench time, is often far smaller than you’d hoped. It appears like your technicians aren’t spending sufficient time actively including worth.

Whereas many organizations monitor wrench time, although, it may well fluctuate broadly, deceptive upkeep departments. On the identical time, time on wrench does have worth as a diagnostic, and avoiding the “wrench time” entice means understanding how and when to make use of it.

Key takeaways

- Focusing solely on wrench time may be deceptive, because it overlooks essential preparatory and supporting actions important for secure and efficient upkeep

- Shift your focus to metrics like PM compliance, schedule compliance, and rework price for a clearer, extra actionable image of your upkeep efficiency

- Digital work orders, cell apps, built-in asset registries, and sensible dashboards are very important for standardizing processes, bettering knowledge high quality, and driving actual effectivity positive factors

Understanding wrench time nuance helps with remodeling upkeep operations, enabling facility managers to keep away from drawing the incorrect conclusions and as an alternative embrace a more practical, data-driven strategy to asset administration and staff productiveness.

What wrench time captures and what it misses

There are numerous drawbacks to utilizing wrench time as a benchmark. Whereas wrench time consists of the hours a technician spends actively performing upkeep duties, it additionally excludes time spent on important actions like studying work orders, accumulating elements or instruments, touring to belongings, or taking mandated breaks.

Whereas these “non-wrench” actions may seem to be downtime, they’re typically important for secure, efficient upkeep. For instance, you need your staff to meticulously put together, confirm security protocols, and pause to troubleshoot mid-task when obligatory. The standard definition of wrench time typically misses the worth these actions add, highlighting the place its measurement can go incorrect, explains practitioner steerage.

When organizations try to measure wrench time, well-liked approaches like self-reports, shadowing a technician, scheduled spot checks, or work sampling typically skew outcomes and might frustrate groups.

Self-reports are likely to overstate productiveness, whereas shadowing can inadvertently alter habits. Sampling struggles with complete protection throughout a number of websites, and statistical evaluation requires rigorous software to keep away from deceptive outliers.

Contemplate this state of affairs: On a sprawling multi-building campus, chilled water pumps start failing through the shoulder season. Initially, wrench time metrics seem favorable as a result of technicians are spending hours on the pumps. Nevertheless, the staff is dropping important time retrieving elements, looking for outdated schematics, and re-doing work attributable to missed steps.

The true answer isn’t merely “extra wrench time.” What you want is to implement standardized digital work orders that embrace asset-specific checklists, up-to-date diagrams, exact half lists, and significant security notes, all accessible to technicians within the subject to drastically cut back delays on the level of labor and shorten restore cycles, resulting in real effectivity positive factors.

Learn how to leverage wrench time as a diagnostic device

Whereas the wrench time metric may be unreliable when you attempt to use it as a main efficiency indicator, it delivers worth as a diagnostic device. You simply should suppose of it much less as a grade on a report card and extra as a symptom that factors to underlying points.

Pinpointing hidden inefficiencies

A low wrench time share isn’t essentially an indication of inefficient technicians. As a substitute, it typically signifies systemic inefficiencies.

Low wrench time numbers spotlight extreme time spent:

- Ready for elements

- Navigating advanced approval processes

- Touring between distant belongings

By observing why wrench time is low in particular situations, you uncover bottlenecks that really hinder productiveness.

So, as an alternative of simply monitoring the quantity, you may conduct focused observations or time research when wrench time dips unexpectedly. Categorize the “non-wrench” actions you observe, letting the granular knowledge reveal the place your staff really loses time and permitting you to handle root causes reasonably than simply lamenting the symptom.

Fashionable facility administration software program options enable you seize this knowledge successfully. For instance, cell work order administration permits technicians to log time towards particular duties and non-wrench actions immediately from their units, offering exact knowledge on the place time goes throughout a job.

Integrating wrench time with broader metrics

For an entire and actionable image, you can’t use wrench time alone. You must pair it with different, extra outcome-oriented metrics.

For instance, in case your wrench time is low however your Imply time to restore (MTTR) can also be excessive, technicians spend plenty of time not wrenching, and the restore nonetheless takes too lengthy once they lastly do. Conversely, a seemingly “good” wrench time may masks frequent reworks or poor schedule compliance if technicians rush by way of duties with out correct preparation.

Use wrench time as a “why” metric. Whenever you see fluctuations or constantly low numbers, cross-reference them along with your MTTR, schedule compliance, and asset reliability knowledge.

Ask your self:

- Does a dip in wrench time correlate with a spike in MTTR? It may point out points with elements availability or documentation

- Does excessive wrench time coincide with low schedule compliance? Maybe technicians spend an excessive amount of time on reactive fixes, pulling them away from deliberate work

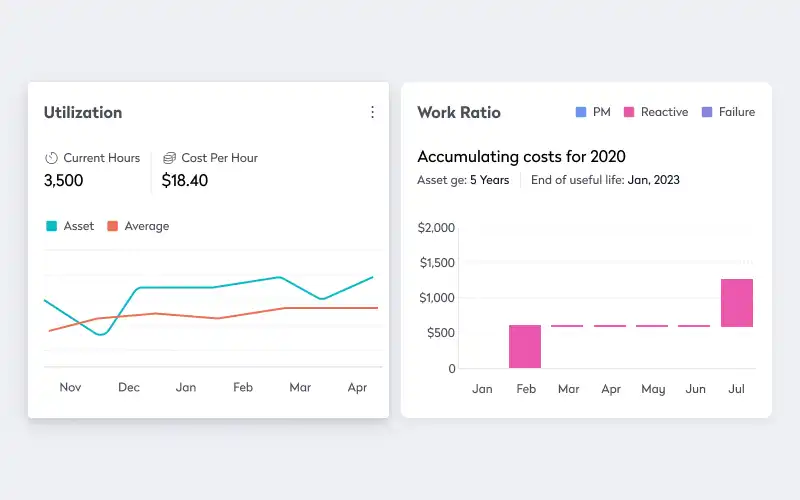

An built-in view helps you ask the proper questions and goal your enchancment efforts successfully. Fashionable platforms with customizable dashboards can help you visualize these interconnected metrics, offering a holistic view of your upkeep operations and enabling you to determine developments and make data-driven choices rapidly.

Learn how to use wrench time to consider implementation effectiveness

After investing in new applied sciences or course of enhancements like digital work orders, cell apps, or enhanced stock administration, wrench time can function a priceless, albeit nuanced, indicator of whether or not these adjustments really impression technician effectivity on the level of labor.

Setting practical expectations

Method this analysis with practical expectations. Whereas the benchmark for world-class wrench time is typically 50–55%, extra typical values are 18–35%, reflecting the fact of non-value-added duties in upkeep workflows.

Your aim, although, isn’t to eradicate these important steps. It’s to attenuate pointless delays. Even probably the most streamlined operations embrace obligatory “non-wrench” actions like security checks, device setup, and documentation.

So, don’t count on your wrench time to immediately leap to 100% after an implementation. As a substitute, search for incremental, sustained enhancements.

A good portion of a technician’s day will all the time contain preparatory and administrative duties. Benchmark your present wrench time earlier than implementation and then measure it once more after an affordable interval to evaluate the change.

Diagnosing post-implementation bottlenecks

If you happen to implement new options designed to scale back non-wrench actions, for instance cell entry to schematics, higher elements monitoring, however wrench time hasn’t improved as anticipated, it’s time to examine additional.

It could be the case that the new cell app isn’t intuitive, main technicians to spend extra time navigating it than anticipated. Or perhaps the new stock system is in place, however groups don’t comply with the method for reserving elements, nonetheless inflicting delays.

If post-implementation wrench time stays stagnant and even decreases, it’s time to conduct follow-up observations.

Ask your self:

- Does the brand new digital work order system really cut back time spent on paperwork?

- Do technicians discover elements extra rapidly with the up to date stock system?

Use wrench time as a suggestions loop. If the numbers don’t transfer in the proper course, your new answer may not be absolutely adopted, correctly configured, or successfully addressing the particular inefficiencies it was supposed to resolve.

From right here, you may fine-tune your implementation and coaching methods for optimum impression.

Extra sensible methods FMs can enhance effectivity with out worrying about wrench time

For a lot of operations, there are numerous more practical methods than monitoring wrench time to tighten processes, enhance asset uptime, and extra simply make and reveal progress towards an efficient, environment friendly facility upkeep administration program.

Standardize preventive upkeep

Construct time- or usage-based preventive upkeep plans on your high-impact belongings. Standardize upkeep checklists so each technician performs the identical steps constantly, and fine-tune the cadence primarily based on noticed failure patterns and operational home windows. By strategically shifting work from reactive to proactive, you considerably reduce unplanned downtime, mitigate threat, and guarantee auditors are happy with clear, full information.

A complete preventive upkeep program inside a contemporary answer means that you can arrange and schedule inspections and duties with configurable maturity charts and stock planning, supporting each time- and usage-based triggers.

Make work orders data-rich and cell

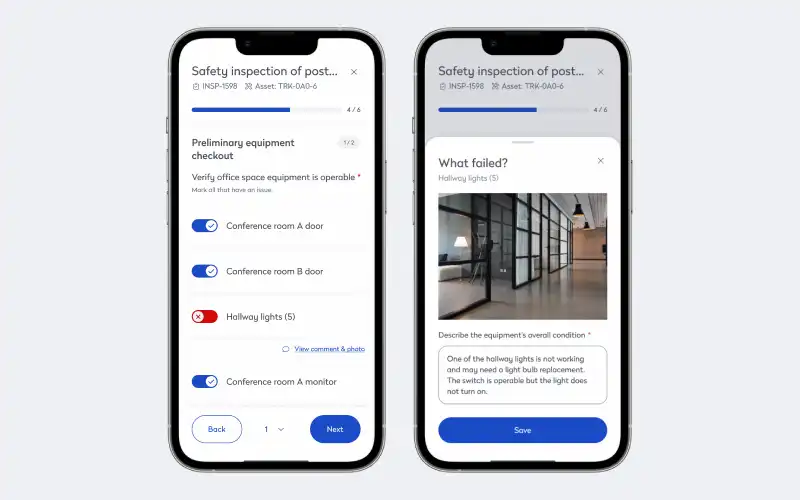

Transfer past cumbersome paper types and fragmented electronic mail chains that break context. Implement configurable digital work orders that seamlessly connect manuals, diagrams, half lists, and security notes, full with checklists that make each step unambiguous, empowering technicians with subject entry to assign, replace, and shut jobs immediately from their cell units.

Managers achieve real-time visibility into the whole lifecycle—from preliminary request to close-out—and might coach groups primarily based on correct, real-world knowledge. Groups can streamline end-to-end workflows with strong work order and ticketing administration, supported by a technician app that features each on-line and offline.

Richer work orders and cell entry dramatically cut back time misplaced looking for data and considerably enhance productiveness on the level of labor, explains uploaded steerage. The result’s sooner close-outs and cleaner asset histories, invaluable for audits and in-depth evaluation.

Contemplate this state of affairs: These thriller chillers cease disrupting manufacturing as soon as work orders ship the identical constant course of each time, full with schematics and required elements. Technicians spend much less time away from the asset, restore cycles shorten, and the MTTR development improves even when the uncooked wrench time share doesn’t dramatically shift.

Implement elements and stock self-discipline

Set up optimum par ranges for important spares, monitor multi-site inventory with common cycle counts, and reserve stock towards scheduled work orders to make sure technicians by no means arrive empty-handed. Crucially, tie stock utilization again to particular belongings and work orders to achieve insights into lifecycle prices and vendor efficiency.

Modernizing this follow with superior elements and stock administration software program helps automated assignments, multi-location monitoring, audits, and correct forecasting.

That is an space the place wrench time typically misleads: excessive “on-tools” minutes throughout a three-hour restore may simply masks poor planning, lacking elements, or prolonged vendor lead occasions. Practitioners observe that bettering planning and supplies administration yields far better positive factors than merely policing technician minutes, in accordance with practitioner views and business analyses.

Contemplate this state of affairs: A multi-site operation constantly experiences Friday delays. Crucial filters go lacking, technicians await deliveries, and weekend time beyond regulation eats into the finances. Leaders implement an answer to set par ranges for these filters, reserve them for PMs, and run cycle counts to preserve correct stock. Emergency orders plummet, schedule compliance rises, and occupied areas stay comfy. The rework price falls as a result of groups constantly use the proper elements the primary time.

Flip visible inspections into structured, digital indicators

Your technicians already use their eyes, ears, and fingers to catch early indicators of potential points alongside the P-F curve. Empower them with standardized digital inspection templates, requiring clear move/fail signoffs, and robotically generate work orders for any recognized defects.

Over time, the patterns of failed checks present invaluable knowledge, indicating the place to regulate PMs or spend money on focused coaching. You may implement this with inspection workflows and steerage that demonstrates how fashionable instruments rework routine checks into insights.

It’s a framework that actively encourages using standardized metrics and procedures to transform subject observations into dependable knowledge that you may leverage into motion.

Construct an built-in asset image

Create a complete asset registry that features full life cycle historical past, guarantee standing, and failure codes, all meticulously mapped to flooring plans and gear areas. Throughout capital planning or portfolio adjustments, the built-in view permits groups to precisely assess deferred upkeep, prioritize important methods, and schedule work with minimal disruption to occupants.

A contemporary facility administration answer with asset administration instruments makes it considerably simpler to visualise belongings, monitor their lifecycles, and join upkeep actions on to reliability analytics.

Implement customizable dashboards

When management asks for a progress report, the reply shouldn’t be a scramble by way of spreadsheets or anecdotal proof. As a substitute, it ought to come from a strong system geared up with intuitive dashboards.

Dashboards are important for facility managers, particularly inside massive enterprises, as they supply a “large image” view by consolidating disparate knowledge right into a single, simply digestible format, serving to you rapidly grasp efficiency, determine developments, and make data-driven choices with out getting misplaced within the numbers.

These instruments enable you rework uncooked knowledge into strategic insights, making it simpler to speak progress, justify investments, and constantly enhance upkeep effectivity throughout the whole operation. By leveraging them, you may lastly transfer from confusion to coordination, making certain each determination is backed by clear, actionable knowledge.

Learn how to assist upkeep groups work smarter, not tougher

By specializing in clear, outcome-driven KPIs, implementing sensible methods like standardized preventive upkeep, leveraging mobile-friendly work orders, and getting critical about elements and stock, facility groups can really rework their operations.

When all this comes collectively, powered by the clear insights from well-designed dashboards, you’re in a position to construct a extra dependable, environment friendly upkeep surroundings.