For facility and upkeep groups, a strong troubleshooting course of helps them be taught from each breakdown, so the following repair is quicker, smarter, and extra dependable. When technicians can entry asset historical past, doc their options, and share data throughout the crew with a digital upkeep administration resolution, troubleshooting turns into a repeatable course of that helps you enhance upkeep insurance policies and processes over time.

Key takeaways

- Troubleshooting is quicker with centralized knowledge. Digital instruments assist technicians entry asset historical past, failure developments, and restore data in seconds

- Standardized workflows cut back guesswork. Step-by-step troubleshooting protocols guarantee constant responses throughout groups and shifts

- Data sharing improves crew efficiency. When insights are documented and accessible, junior technicians can clear up issues with out counting on senior employees

Key options of a trendy facility administration resolution assist upkeep groups flip scattered knowledge into actionable troubleshooting insights.

Troubleshooting in facility and upkeep administration: The artwork and science of discovering fixes sooner

Troubleshooting is the method of diagnosing and resolving issues in tools, techniques, or processes. When the crew has a dependable systematic course of in place, troubleshooting reduces downtime, improves security, and extends asset life.

Troubleshooting isn’t nearly fixing what’s damaged, although. It’s about studying from each breakdown. When technicians doc what went mistaken and the way they resolved it, they create a data base that helps your entire crew reply sooner subsequent time, and that’s particularly vital in environments with excessive asset quantity or restricted staffing, the place repeat failures can shortly disrupt operations.

A structured troubleshooting course of additionally helps standardize responses throughout shifts and areas. As an alternative of counting on reminiscence or guesswork, technicians can entry asset historical past, failure codes, and documented options from related incidents.

You get fewer delays, fewer errors, and extra constant outcomes.

With the fitting instruments, troubleshooting turns into a repeatable course of that improves over time. Groups construct confidence, cut back reliance on senior employees, and make smarter selections based mostly on actual knowledge, not assumptions.

Entry full asset historical past in seconds

Attempting to troubleshoot with out context results in repeated failures. Technicians want entry to current work orders, inspection outcomes, and substitute half data to make knowledgeable selections.

As an alternative of digging by way of spreadsheets or paper logs, a digital FM resolution shops all the things in a single place.

Technicians can pull up:

- Upkeep historical past

- Restore notes

- Inspection reviews

- Components specs

- Producer manuals

- Guarantee info

For instance, a technician at a bottling plant is known as to repair a conveyor motor that retains stalling. They entry the asset report and see that the motor was changed twice within the final six months. Reviewing the inspection logs, they discover a recurring observe about warmth harm. They verify the air flow specs and uncover the cooling fan is undersized. With the fitting knowledge, they clear up the foundation problem as an alternative of repeating the identical restore.

Use checklists to remove the plain

Leaping to conclusions can waste time and result in incorrect repairs. A greater strategy is to rule out the obvious causes first, for instance improperly put in elements or missed harm.

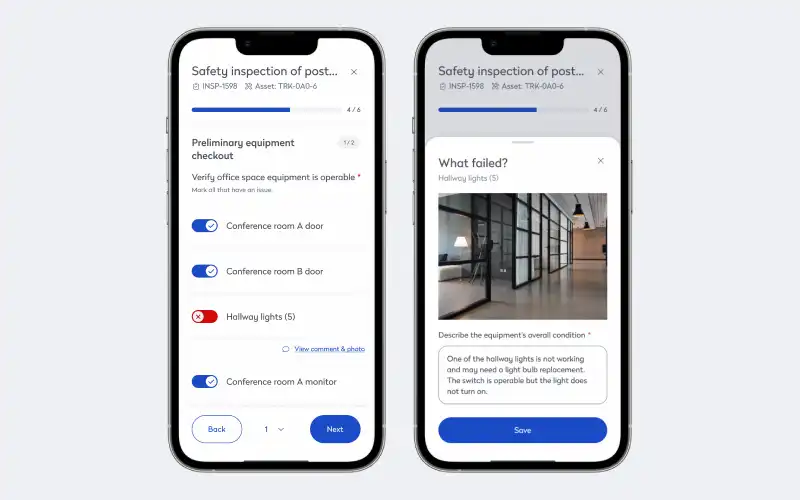

Digital checklists information technicians by way of a structured course of, combining their expertise with real-time knowledge. The system helps them remove widespread points and deal with what’s more than likely to be the foundation trigger.

Technicians can:

- Comply with asset-specific troubleshooting workflows

- Log every step taken and outcome noticed

- Connect images or movies to verify findings

- Flag anomalies for supervisor overview

So, at a distribution heart, a technician must repair a dock door that gained’t shut. The guidelines prompts them to confirm energy, examine the management panel, and verify the observe. They log every step and connect a photograph exhibiting a bent observe. The guidelines helps them keep away from losing time on electrical diagnostics.

Archive insights to construct team-wide data

Troubleshooting is a component science, half expertise. When technicians doc their theories and options, they create a data base that helps your entire crew.

A facility administration resolution makes it simple to connect notes, images, and observations to asset data. The following time the identical problem happens, technicians can seek for related failures by asset sort or location, overview earlier diagnoses and fixes, after which be taught from documented finest practices.

For instance, a junior technician at a resort is assigned to repair a leaking dishwasher. They search the asset report and discover a observe from a earlier restore that recognized a cracked seal. They examine the identical space, affirm the difficulty, and repair it without having to escalate. Their replace provides a photograph and half quantity for future reference.

Observe failure codes to identify recurring points

Lots of issues don’t occur simply as soon as. If a breakdown retains taking place, it’s an indication of a deeper problem. With failure codes and standardized classes, you possibly can observe developments throughout belongings and areas.

Digital FM instruments allow you to:

- Assign constant failure codes to every breakdown

- Filter breakdowns by sort, frequency, and trigger

- Generate reviews to determine recurring points

- Prioritize fixes based mostly on impression and urgency

At a producing aircraft, a packaging machine jams each night time shift. Technicians log every incident with the failure code “mechanical obstruction.” The upkeep supervisor runs a report and sees the identical code throughout three machines. They hint the difficulty to a faulty gear mannequin and exchange it throughout the road.

Doc options to assist steady enchancment

Troubleshooting doesn’t finish when the asset is again on-line. The closing step is documenting what labored. That info feeds into your preventive upkeep technique and helps junior technicians be taught from previous repairs.

With a centralized system, each resolution turns into a part of the asset’s historical past, so that you can:

- Document the ultimate analysis

- Log the restore steps taken

- Connect images or movies of the repair

- Be aware any follow-up actions required

At a municipal water remedy plant, a pump fails attributable to cavitation. The technician adjusts the inlet stress and logs the repair, together with a video and a observe about figuring out signs. Months later, a brand new technician resolves the same problem in minutes by reviewing the archived resolution.

Suggestions for higher asset and tools upkeep troubleshooting

A strong troubleshooting course of begins with good habits that assist technicians keep centered, cut back errors, and make smarter selections in the second.

- Begin with the fundamentals: All the time confirm energy, connections, and settings earlier than diving into deeper diagnostics. Many points stem from easy oversights which are simple to repair as soon as recognized

- Use the asset report as your information: Reviewing previous work orders, inspection notes, and restore historical past can reveal patterns that time to the foundation trigger. Context helps technicians keep away from repeating the identical repair with out fixing the underlying problem

- Comply with a guidelines, even when you already know the asset: Structured workflows cut back bias and guarantee no steps are skipped, particularly beneath time stress. Familiarity can result in assumptions, however a guidelines retains the method constant

- Doc all the things: Notes, images, and movies from every restore create a reference for future troubleshooting. Documentation helps different technicians clear up related issues sooner and with extra confidence.

- Tag recurring points with failure codes: Constant coding makes it simpler to trace developments throughout belongings and areas. Over time, this knowledge helps prioritize preventive fixes and cut back repeat breakdowns

- Ask for enter, then share your findings: Collaboration improves accuracy and helps uncover blind spots. When technicians share what they be taught, the entire crew advantages from stronger collective data

- Don’t rush the closing step: As soon as the asset is again on-line, take time to log the answer and any follow-up actions, so your closing step turns a fast repair right into a long-term enchancment

Troubleshooting is a component technical ability, half course of self-discipline. When technicians mix expertise with structured workflows and shared knowledge, they clear up issues sooner and construct a stronger upkeep tradition.

Share centralized knowledge to troubleshoot smarter

Troubleshooting shouldn’t must depend on reminiscence or guesswork. With a digital facility administration Troubleshooting is an opportunity to strengthen your upkeep technique. With centralized knowledge and structured workflows, technicians can reply shortly, make knowledgeable selections, and doc each repair to assist long-term enchancment. A digital facility administration resolution helps groups cut back repeat failures, enhance consistency throughout shifts, and construct a shared data base. When each restore provides to your understanding, your crew turns into extra assured, extra environment friendly, and higher ready for the following problem.