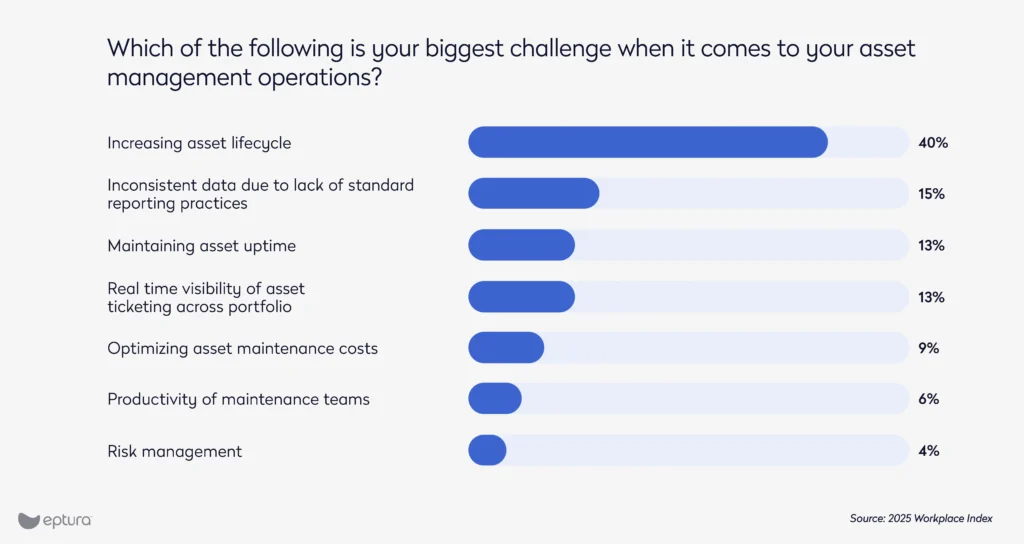

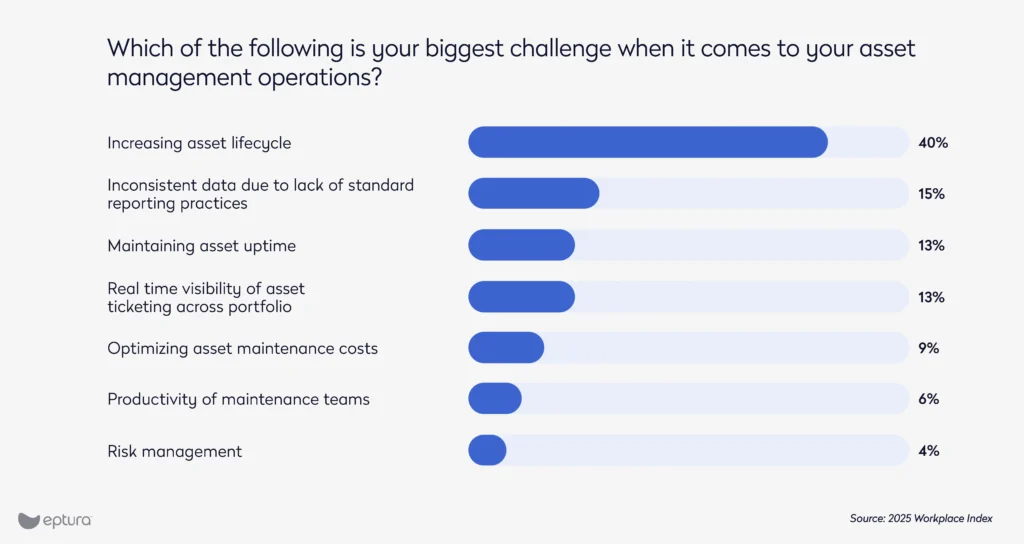

With the present and potential disruptions to the worldwide provide chain, enterprises are placing danger administration entrance and middle in a noticeable uptick from the beginning of the yr. Within the January survey of operational leaders featured in our 2025 Office Index, most firms didn’t prioritize danger mitigation within the context of managing their bodily property. When requested, “Which of the next is your greatest problem in relation to your asset administration operations?”, “Danger administration” was the least in style reply at 4%. The preferred, “Rising asset lifecycle,” was ten occasions increased.

At the moment, respondents additionally indicated that decreasing danger was not a high consideration of their long-range operational planning. When requested, “What’s your key goal for the subsequent 24 months in relation to asset administration?”, solely 2% selected danger mitigation.

Now, nevertheless, we’re seeing firms refocusing on danger, particularly in industries that depend on their property to make merchandise or ship providers like healthcare, airways, manufacturing, fleet and transportation, and vitality and utilities.

Whereas there’s been much less of a shift in industries which are extra purely service-based, provide chain points can have an effect on anybody. For instance, organizations planning renovations or upgrading their workplace furnishings could have to re-examine undertaking budgets. Some skilled providers companies may even leverage present developments so as to add worth for shoppers. Accounting corporations, for instance, may supply asset-reliant firms insights into their present provide chains and recommendation on the place to optimize.

What firms can management: Cross-departmental complexity of the process to pay processes

The procure-to-pay (P2P) course of encompasses the complete cycle from figuring out the necessity for items or providers to creating the ultimate fee to suppliers. It’s important for sustaining operational effectivity, guaranteeing monetary accuracy, and fostering robust relationships with suppliers.

One in all its defining options is that it’s a cross-departmental course of, requiring coordination from groups throughout the enterprise, together with:

- Procurement: Accountable for figuring out wants, deciding on suppliers, and managing the acquisition requisition and buy order processes

- Finance: Handles the monetary features, together with budgeting, bill verification, and fee processing

- Accounts payable: Particularly manages the receipt and processing of provider invoices, guaranteeing they’re correct and paid on time

- Operations: Ensures that the products or providers obtained meet the required requirements and are built-in into the corporate’s operations

- Authorized: Opinions and approves contracts and phrases with suppliers to make sure compliance with authorized and regulatory necessities

- High quality management: Inspects and verifies the standard of the delivered items or providers to make sure they meet the group’s requirements

In asset-heavy industries like manufacturing, building, and logistics, the procurement crew sources high-value property akin to specialised equipment and uncooked supplies, whereas the finance division manages budgeting and ensures correct bill verification and well timed funds. For instance, in building, the accounts payable crew verifies invoices for big gear leases to keep away from overcharges. The operations crew ensures that obtained items, like new fleet automobiles in logistics, meet the required requirements. The authorized division opinions contracts for compliance, and high quality management groups examine supplies and gear to make sure security and efficiency.

Simply as essential as anybody crew’s work is their means to share information and coordinate duties throughout departmental strains. Nevertheless, each enterprise perform has its personal targets, which may create imbalances between groups.

Accounts payable and procurement: Money steadiness versus provider relationships

The accounts payable crew typically goals to pay invoices solely when they’re resulting from maximize the corporate’s money circulate. This technique may help in sustaining a better money steadiness, which is helpful for monetary flexibility and curiosity earnings. Nevertheless, procurement departments wish to construct and keep robust relationships with the absolute best suppliers. These suppliers could choose shorter fee phrases to make sure their very own regular money circulate. Delayed funds pressure provider relationships, probably resulting in increased prices, lowered service high quality, and even provide chain disruptions.

Procurement and high quality management: Quick-term financial savings versus long-term prices

The procurement division could prioritize price financial savings and effectivity, which may typically result in the choice of lower-cost suppliers. Whereas this will cut back instant bills, it may additionally introduce dangers associated to the standard of products or providers. The standard management division, however, focuses on guaranteeing that the standard of delivered objects meets the group’s requirements. Poor high quality can result in increased long-term prices, akin to returns, rework, and buyer dissatisfaction.

All of those challenges enhance as firms scale. As a result of the foundation trigger for all these points is lack of organizational alignment, the bigger the corporate, the extra crucial it turns into to agree on the correct steadiness between crew goals up entrance.

When the departments work collectively, Procurement can prioritize price financial savings whereas serving to High quality Management guarantee items and providers meet requirements. By collaborating intently, the procurement crew can collectively consider suppliers with high quality management to make sure that lower-cost gear elements, for instance, don’t compromise high quality. High quality management gives ongoing suggestions on the efficiency and reliability of delivered objects, serving to procurement to make higher knowledgeable selections. The partnership ensures that every one bought property meet the required requirements, decreasing the danger of returns, rework, and buyer dissatisfaction.

The place firms can mitigate danger: Exterior components affecting the provision chain

There are numerous hyperlinks in any provide chain that an organization can’t management.

Pure disasters, akin to hurricanes, earthquakes, and floods, can disrupt the provision chain by damaging infrastructure, disrupting transportation, and inflicting manufacturing delays. For instance, a manufacturing unit in a disaster-prone space is likely to be pressured to close down, resulting in a scarcity of crucial elements.

Human components like commerce insurance policies, political instability, and worldwide conflicts also can considerably have an effect on the provision chain. Adjustments in commerce rules, akin to tariffs and import/export restrictions, can enhance prices and create delays. Political instability in provider international locations can result in provide disruptions, whereas worldwide conflicts may end up in sanctions or embargoes that restrict entry to sure supplies or markets.

Compounding the problem is that the worldwide provide chain is a dynamic and ever-changing setting. Market circumstances, buyer calls for, and technological developments are always evolving. Corporations have to design their asset upkeep processes – from discovering methods to extend the life cycle of mission-critical gear to diligently managing elements stock and suppliers – to be agile and responsive. For instance, a sudden surge in demand for a product can pressure the provision chain, whereas new applied sciences can render present processes out of date.

How an enterprise can enhance: Counteracting complexity and mitigating danger by transferring towards the correct on the worth chain

When provide chains sluggish and shrink, organizations begin asking themselves powerful questions on their present operations. Siloed techniques make it exhausting to even discover correct solutions, whereas linked, clever workflows empower firms to create options.

For instance, an organization that finds itself going through a brand new tariff would wish to know:

- What’s the supply of the fee enhance?

- Is it coming from a single nation?

- How a lot of our manufacturing relies in that nation?

- How a lot labor do now we have in that nation?

- The place does the output from that nation go by way of our buyer base?

- Who’re these clients?

- Which clients are least (or most) delicate to cost adjustments?

- What are our contractual obligations?

- Do our contracts with clients permit us to go on the elevated prices?

- Do now we have any contractual agreements with distributors that permit us to push again on the fee enhance?

- How will tariff-related provide chain disruptions influence our service stage agreements, and the way can we mitigate this?

In a siloed strategy, every division may focus by itself instant considerations with out contemplating the broader implications of their solutions. The result’s fragmented decision-making and elevated vulnerability to provide chain disruptions.

A extra built-in strategy includes cross-departmental collaboration and a holistic view of the provision chain that additionally consists of an correct understanding of on-hand stock and forecast use charges. By working collectively, departments can establish and implement methods to mitigate the influence of price will increase. For instance, procurement may discover various suppliers, finance may alter pricing methods, and operations may optimize manufacturing processes to cut back prices.

To debate methods to optimize your asset operations and handle danger, join with our consultancy.