Area technicians are already working in difficult situations, from deep inside manufacturing amenities stretched throughout multi-site portfolios to touring between wind generators separated by miles of rural terrain. They navigate basement mechanical rooms with no cell sign, carry out upkeep on electrical infrastructure spanning a whole bunch of miles, and troubleshoot important gear inside oil and gasoline constructions the place house is tight and stakes are excessive.

Managing operations throughout these distributed, usually remoted work environments requires extra than simply proficient technicians, although. You want expertise constructed for the realities of the discipline.

Key takeaways

- First-time repair charge is your most actionable metric: The hole between common and best-in-class efficiency interprets on to operational prices via repeated truck rolls, wasted labor, and buyer dissatisfaction throughout your portfolio

- Offline performance isn’t optionally available for discipline work: Your technicians work in environments the place connectivity fails frequently. True cell platforms should seize knowledge, sync routinely, and resolve conflicts with out requiring fixed sign

- Cell instruments unify fragmented operations: When work orders, asset intelligence, security compliance, and inspection knowledge dwell in a single platform, your discipline groups achieve the context they should full jobs on the primary go to

Main organizations are investing in platforms that allow distributed workforces to function effectively throughout complicated, geographically dispersed asset portfolios, even when connectivity is unreliable, and work situations are removed from splendid. In truth, the sector service administration (FSM) market is predicted to develop from roughly $5.1 billion in 2025 to $9.17 billion by 2030, in accordance with MarketsandMarkets.

Regardless of this transfer out there, many organizations nonetheless function with fragmented techniques. One app handles work orders. Clipboards monitor security procedures. Excel manages elements stock. Technicians toggle between instruments, managers lack real-time visibility throughout websites, and compliance officers spend audit season monitoring paper trails from a number of places.

The best way to enhance first-time repair charge in discipline service

First-time repair charge (FTFR) measures the proportion of service calls resolved on the primary go to, with out requiring a callback or extra journey. Business common FTFR hovers round 80%, whereas best-in-class organizations obtain 88% or greater, in accordance with analysis from PTC and Aberdeen Group.

That 8-point hole between common and glorious interprets on to operational prices and buyer satisfaction.

Each missed first go to sometimes requires 1.6 extra dispatches at $200–$300 per truck roll, in accordance with Area Service Information business benchmarking. For a staff dealing with 1,000 service calls month-to-month with an 80% FTFR, you’re sending technicians again out 200 instances unnecessarily. That’s roughly 320 additional truck rolls monthly, costing between $64,000 and $96,000 in wasted labor and journey each month.

The issue compounds when you’re managing a number of websites throughout an enterprise portfolio. A failed first go to at your Chicago facility doesn’t simply value one truck roll—it means coordinating schedules throughout time zones, probably pulling a specialist from one other area, and explaining delays to constructing occupants who anticipated the problem resolved yesterday.

Greatest offline cell apps for discipline technicians

You ship a technician 90 miles out to service wind generators on a distant wind farm. No cell sign. Or they descend right into a basement utility tunnel beneath your campus to examine mechanical techniques. Connection drops. In each eventualities, in case your cell app requires fixed connectivity, work stops, or you’re playing on reminiscence and paper notes.

This isn’t a minor inconvenience when you’re managing property throughout a number of websites or distant places. A technician working via offshore oil platforms, utility substations in rural areas, or dense manufacturing amenities with RF interference can’t afford to lose entry to work orders, asset histories, or security procedures.

True offline performance should embrace:

- Full knowledge seize with out connectivity: Signatures, pictures, time logs, gear readings, and notes all save domestically with none sign

- Automated synchronization: Every little thing syncs when connection returns, with out handbook re-entry or knowledge loss

- Battle decision controls: Outline how the system handles edits when two technicians modify the identical work order offline

Collectively, these capabilities guarantee technicians keep full productiveness no matter connectivity, eliminating the pricey delays and knowledge recreation that plague conventional cell apps.

Cell asset administration techniques for discipline service

Conventional workflows ship your technicians to websites, whether or not that’s constructing 47 of your company portfolio or a distant pump station, with a piece order quantity and minimal context.

They arrive, assess the state of affairs, and uncover they want an element that’s again at your central warehouse. Or they lack the technical documentation to troubleshoot a fancy system. Now you’re scheduling callbacks, losing drive time, which issues extra when websites are many miles aside, and explaining delays to pissed off stakeholders.

Asset intelligence platforms ought to ship prompt entry to:

- Full asset historical past: Previous work orders, recurring failures, final preventive upkeep date, and compliance inspection data

- Producer documentation: Working manuals, wiring diagrams, and technical specs

- Actual-time elements stock: On-hand portions at your nearest warehouse or service car

- Security documentation: Knowledge sheets and security procedures accessible offline

So, your technician is servicing elevators throughout a college campus with 30 buildings. They scan an elevator’s QR code and instantly see that its final preventive upkeep was eight months in the past, two months overdue. The system then serves up your customary PM guidelines and confirms the wanted elements are of their truck.

They full service in one go to as an alternative of creating two journeys throughout campus or, worse, returning out of your predominant facility throughout city.

Digital security checklists for discipline technicians

Paper-based security procedures create gaps in your operations, notably when you’re managing work throughout a number of websites or in high-risk environments like confined areas inside industrial amenities.

Illegible handwriting on permit-to-work varieties. Lacking signatures on lockout/tagout (LOTO) checklists. Paperwork misplaced in transit between your Denver facility and your Austin workplace. Types sitting in vehicles whereas you don’t have any visibility into what’s really occurring within the discipline.

When security documentation lives separate out of your core work administration system, your technicians working alone at distant websites or deep inside complicated constructions face an unimaginable selection: skip steps to save lots of time or do double knowledge entry that no person values.

LOTO requirements require documented power management procedures with verified isolation and licensed signatures, in accordance with OSHA rules. For organizations working throughout a number of websites, this implies sustaining constant security requirements whether or not your technician is working in your flagship constructing or at a distant location three states away.

Think about your technician is performing electrical upkeep on energized gear at a distant facility requiring a three-step LOTO sequence.

First, their supervisor critiques the work plan remotely and grants permission electronically. Second, your technician images the put in locks to confirm correct isolation. Third, the system logs completion with timestamps and all required signatures. You possibly can see compliance standing in real-time throughout all websites. You now have an entire, centralized compliance path with out slowing down discipline work.

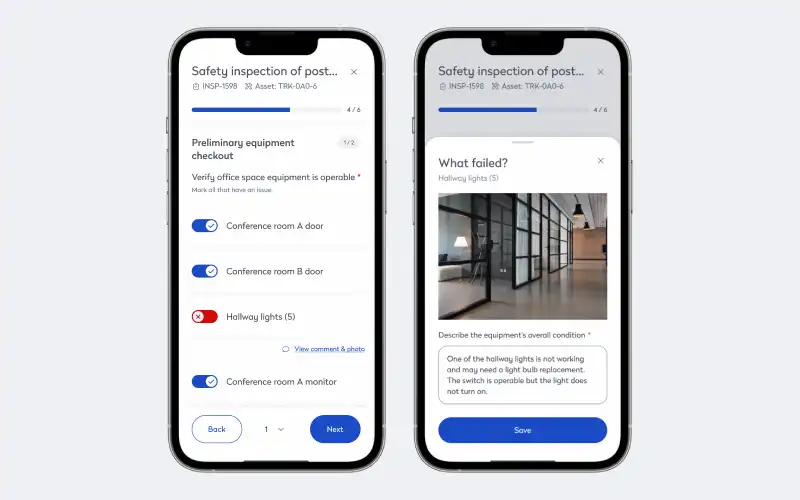

Cell inspection software program for preventive upkeep

Cell inspection instruments let your technicians seize actual gear situations throughout all websites, together with strain readings, temperature measurements, vibration ranges, visible observations. When readings fall outdoors acceptable thresholds at any location, the system routinely generates follow-up work orders with applicable precedence and ability necessities.

It’s an strategy that helps you leverage the P-F curve, providing you with visibility into the interval between when gear begins deteriorating and when it fails. By catching points in that window, you may schedule repairs strategically slightly than responding to emergency breakdowns.

Image month-to-month hearth suppression system inspections throughout a 45-building healthcare campus. Any “low strain” readings at any location routinely generate recharge work orders assigned to licensed technicians in that area.

Constructing mobile-first operations that work in every single place

Cell discipline service capabilities have advanced from aggressive edge to operational necessity. Whether or not you’re managing company actual property throughout 20 cities, sustaining utility infrastructure throughout rural territories, or protecting industrial amenities working throughout a number of continents, your groups want instruments that work in basements, on rooftops, at distant websites, and in every single place in between.

Join with our discipline providers specialists to see how Eptura handles offline work, asset intelligence, and security compliance in a dwell demo.