Each steady operations facility has this second: Second shift walks in, sees a cryptic sticky be aware on a machine, and has no concept what first shift was coping with. Or worse, they don’t see the be aware in any respect. When the gear on the manufacturing line fails three hours into the second shift, manufacturing stops. No person is aware of what the day shift technician tried.

Poor handoff practices price industrial producers $50 billion yearly in keeping with a Deloitte business report, whereas unscheduled downtime prices amenities $260,000 per hour throughout roughly 800 hours per 12 months, with communication breakdowns chargeable for 20% to 30% of incidents. Staff waste 1.8 hours on daily basis looking for data their predecessors ought to have documented, in keeping with a McKinsey report.

The answer is a unified digital asset and gear platform that ensures essential information flows seamlessly between shifts.

Key takeaways

- Important gear information that stays undocumented leaves incoming shifts with out context, forcing groups to rediscover points, repeat diagnostics, and make choices blind to what earlier shifts noticed or tried

- Poor shift handoffs drain billions yearly from producers, with communication breakdowns chargeable for a good portion of unplanned downtime incidents that deliver manufacturing to a halt and create cascading operational prices

- Unified digital platforms with mobile-first entry get rid of data gaps by capturing structured shift information, delivering real-time alerts to incoming groups, and connecting handoff documentation on to asset administration and work order methods

With out structured data switch between shifts, firms face increased prices, decrease productiveness, and cascading high quality points that erode aggressive place.

Why continuity now defines operational excellence in manufacturing

Continuity represents greater than simply good communication between shifts. Manufacturing continuity means sustaining unbroken operational information throughout shifts so incoming groups can decide up precisely the place earlier groups left off.

When the second shift inherits full context about gear standing, creating points, and work in progress, they can make knowledgeable choices that forestall small issues from turning into main failures.

Manufacturing amenities lose continuity when essential information exists solely within the reminiscences of departing shift employees.

The day shift technician who observed a bearing working sizzling by no means documented the commentary. The primary shift operator who adjusted machine parameters to compensate for materials variations didn’t document the modifications. The outgoing supervisor who deliberate to order substitute elements forgot to say it in the course of the rushed five-minute handoff. Every hole in continuity creates threat.

Continuity transforms tribal information into institutional information. Tools doesn’t care which shift operates it, and prospects don’t distinguish between merchandise manufactured throughout day versus evening shifts. Attaining constant output throughout all shifts calls for continuity methods that seize and switch full operational context mechanically.

The monetary influence of poor continuity in manufacturing extends throughout operations

Tools runs at decreased capability when incoming operators lack context about creating points. High quality defects multiply when groups miss essential course of changes. Rework and scrap charges climb when shift transitions lose details about parameter modifications.

Security creates further prices and dangers. Analysis from business sources exhibits producers report security incidents elevated over current years. Many incidents happen throughout or shortly after shift handovers, when incoming groups lack consciousness of hazards or gear standing.

How unified facility administration platforms ship shift handoff excellence

Producers obtain shift handoff excellence by unified platforms that seize essential data systematically and ship it precisely when and the place incoming groups want context. The framework replaces casual verbal handovers with structured digital methods constructed on three parts.

Structured automated information seize replaces ad-hoc notes

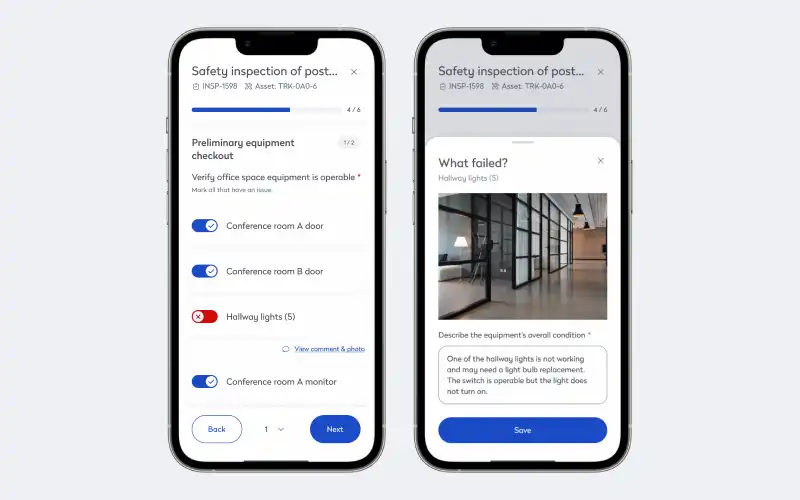

Digital work order methods substitute free-form note-taking with systematic information seize. Groups doc gear standing at shift finish utilizing customizable work order templates with required fields reasonably than non-obligatory narratives. Work in progress will get recorded with particular subsequent steps and hooked up documentation together with checklists, diagrams, and schematics. When groups establish points throughout their shift, they’ll embrace actions taken, elements used, and outcomes.

Tools-specific documentation covers present operational standing, current upkeep or repairs, uncommon habits or creating points, and parameter modifications. Security and compliance documentation captures incidents or near-misses, lockout and tagout standing, environmental considerations, and regulatory inspection notes, whereas preventive upkeep scheduling ensures groups doc creating points earlier than they escalate into failures.

Cellular accessibility delivers data on the level of labor

Cellular technician apps allow technicians to entry full handoff data at machines reasonably than returning to workplaces to verify notes. Actual-time updates develop into seen to incoming shifts instantly.

Cellular platforms assist picture documentation and video seize, permitting visible proof to complement textual content descriptions. Barcode or QR code scanning identifies particular belongings and retrieves full upkeep histories with a single scan. Offline performance maintains productiveness when community connectivity drops, however syncs mechanically when connections restore, guaranteeing no data will get misplaced throughout shift transitions.

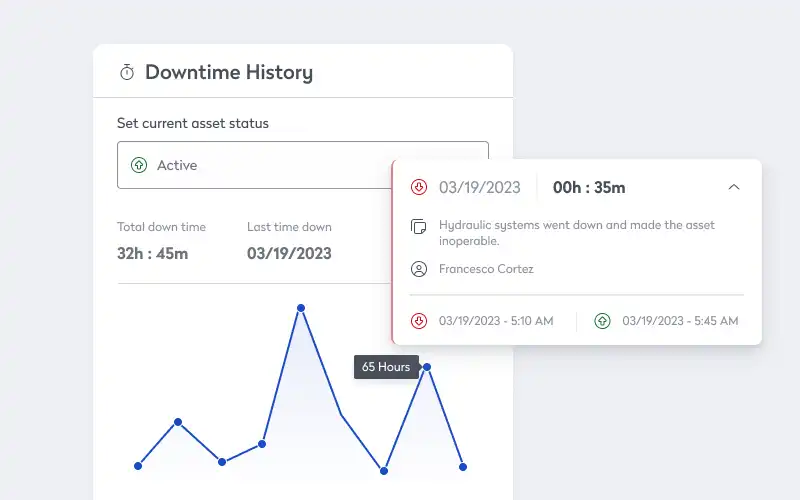

An evening shift operator discovering a hydraulic leak at 11 takes pictures by the cellular app, tags the difficulty with severity markers, and paperwork containment steps together with elements used from stock. The day shift supervisor receives alerts at 6:30 with full context, pictures, precedence indicators, and full labor and elements information. Elements orders exit earlier than arriving on-site, decreasing response time from hours to minutes.

Visible dashboards present at-a-glance operational standing

Actual-time visibility throughout whole operations permits managers to identify creating points earlier than they escalate. Unified facility administration platforms consolidate dashboard parts that show gear uptime by shift and manufacturing line, work order standing and growing old, preventive upkeep compliance charges, high quality metrics and defect traits, and security incident monitoring.

Drill-down capabilities let managers examine root causes and entry full work order histories together with labor hours, elements prices, and vendor efficiency. Automated alerts notify stakeholders when metrics exceed thresholds, guaranteeing essential data reaches decision-makers instantly reasonably than ready for shift handoff conferences.

Measuring outcomes by operational metrics

Measuring enchancment in shift handoff excellence requires monitoring each main indicators that predict efficiency and lagging indicators that verify outcomes. Unified facility administration platforms seize these metrics mechanically reasonably than requiring handbook compilation from disparate sources.

Main indicators predict handoff high quality

Handoff completion price measures the share of shifts with totally accomplished digital handoffs, indicating crew adoption and course of compliance. Time to handoff completion tracks how lengthy groups spend on documentation. Challenge escalation price exhibits the share of flagged gadgets correctly escalated. Data completeness calculates the share of required fields populated.

Lagging indicators verify operational outcomes

Unplanned downtime discount measures the objective, with digital handovers usually contributing to vital enhancements as groups catch creating points earlier and reply sooner with higher context. Imply time to restore decreases when technicians arrive with full data reasonably than beginning analysis from scratch. Schedule compliance improves as preventive upkeep occurs on time, driving down reactive work charges.

Actual success story: How digital preventive upkeep improved productiveness, decreased threat

A world gear producer with 1,300 staff confronted rising challenges sustaining operational effectivity throughout a number of shifts. Paper-based preventive upkeep processes have been time-consuming, error-prone, and created compliance dangers. Restricted visibility into asset well being made planning troublesome. Handbook record-keeping threatened audit readiness.

The ability deployed Eptura Asset to digitize preventive upkeep workflows. Groups created standardized inspection templates utilized throughout a whole lot of belongings, enabling automated failure work orders and real-time monitoring. Technicians adopted cellular apps for on-the-go updates, whereas managers leveraged dashboards for data-driven choices.

After a profitable implementation, they realized:

- 100% transition from paper-based to digital preventive upkeep

- Improved audit readiness and compliance confidence

- Sooner work order creation by automated inspection workflows

- Elevated technician productiveness with cellular app adoption

- Standardized processes throughout a number of amenities

The success of the preliminary implementation led to coaching rollout throughout different amenities, establishing constant upkeep excellence practices all through the group.

Learn the full success story.