The challenges proceed to climb for facility and upkeep managers. Producers count on enter prices to extend by a median of 5.4% over the following 12 months, based on Deloitte’s 2026 Manufacturing Trade Outlook. In the meantime, growing old gear and an growing old, retiring workforce are amplifying restore and downtime prices, with 25% of the manufacturing workforce now at or past eligible retirement age.

Reliability centered upkeep (RCM) helps you overcome these challenges via a scientific course of that matches important property with probably the most cost-effective upkeep methods. As an alternative of making use of blanket preventive upkeep schedules or working gear to failure, RCM allows organizations to optimize useful resource allocation based mostly on asset criticality, failure modes, and enterprise influence.

Key takeaways

- Organizations battle to stability short-term operational calls for with long-term asset stewardship, typically leading to deferred upkeep and reactive decision-making that perpetuates cycles of underinvestment

- RCM analyzes seven important questions on every asset to decide optimum upkeep methods, shifting past producer suggestions to deal with facility-specific working situations and enterprise necessities

- Efficient implementation requires understanding asset criticality, analyzing failure modes and penalties, and repeatedly refining upkeep approaches as enterprise targets and gear situations evolve over time

Understanding how organizations obtain these outcomes requires analyzing the basic rules that differentiate RCM from conventional upkeep approaches.

What’s reliability centered upkeep and why does it matter?

Reliability centered upkeep began in the aviation trade, the place the complexity of plane techniques, heavy operational calls for, and catastrophic failure dangers required a extra refined framework than time-based preventive upkeep alone may present.

RCM focuses on figuring out the upkeep technique that delivers most reliability on the lowest whole value for every particular asset. The guideline acknowledges that totally different property require totally different administration approaches. Some property demand steady high-tech monitoring via predictive upkeep packages, whereas others carry out optimally underneath run-to-failure fashions.

The stress to scale back prices whereas sustaining efficiency creates rigidity that usually results in substantial deferred upkeep and reactive firefighting. Organizations implement RCM to interrupt this cycle by aligning upkeep methods with broader enterprise targets whereas demonstrating the tangible worth of proactive asset administration.

Vaughn Halliday, Supervisor of Help Companies and Services for the Central Financial institution of Trinidad & Tobago, defined in a current Asset Champion podcast episode, “Organizations face the problem of balancing short-term operational calls for in opposition to that long-term asset stewardship. There’s at all times this fixed stress, particularly in these fashionable days, to scale back prices, however there’s nonetheless the expectation for high-performance, sustainable environments, and that expectation retains rising.”

What are the seven RCM questions each facility supervisor ought to ask?

RCM methodology entails working via seven elementary questions for every asset or system. These questions create a structured framework that strikes organizations from assumptions to evidence-based upkeep selections.

What’s the asset purported to do, and what are its efficiency requirements?

The primary query establishes what the asset or gear is meant to do and the related efficiency requirements. Organizations study producer documentation to grasp the scope of features, limitations, and correct strategies of use regarding security and environmental measures. An industrial scale, for instance, could have particular weight limits that have an effect on accuracy, plus exact necessities for merchandise placement and environmental situations to make sure dependable operation.

How properly is the asset performing in comparison with desired outcomes?

Organizations assess present asset efficiency in opposition to desired outcomes. A conveyor belt shifting 5,000 bins between breakdowns, with every breakdown lasting three hours, might need the potential to maneuver 7,000 bins between failures whereas decreasing breakdown length to 2 hours based mostly on producer specs, upkeep group experience, and information within the facility administration system.

In what methods can this gear fail?

Services decide precisely how gear can fail to supply required features. The evaluation identifies whether or not failures relate to particular elements or characterize systemic points, how typically failures happen, and whether or not failure patterns have an effect on a number of items of the identical gear sort throughout the group.

What causes every sort of failure?

Understanding why, when, and the way gear failures happen offers important perception. Heavy-use gear could endure from working fatigue. Environmental situations, together with warmth, chilly, or moisture publicity, create stress. Human error and inherent design or manufacturing flaws additionally contribute to gear failure. Figuring out root causes allows organizations to deal with underlying points somewhat than treating signs.

What occurs when the asset fails?

Failure results vary from almost undetectable efficiency degradation to finish lack of perform. Tools failure would possibly lower output pace or high quality, or it would end in full operational shutdown. Organizations consider how failures influence productiveness, operations, capital prices, security dangers for operators, environmental compliance, and total asset integrity.

Why does this failure matter to the general enterprise?

Past monetary and logistical penalties, amenities assess security dangers and environmental impacts related to potential failure mode. The evaluation considers how failures have an effect on asset situations and decide the applicable stage of intervention based mostly on whole enterprise influence.

What proactive upkeep prevents or reduces failure penalties?

Asset upkeep and restore histories reveal breakdown patterns that information preventive measures. A conveyor belt that usually runs 5,000 bins earlier than requiring repairs would possibly profit from visible inspections after each 4,500 bins to increase uptime. Nonetheless, organizations should stability what they will do in opposition to what they need to do. When the price and complexity of stopping breakdown exceed the worth of elevated uptime, run-to-failure stays the optimum technique.

What expertise and software program allow reliability centered upkeep?

Fashionable facility administration platforms present the information basis essential for efficient RCM packages. IFMA’s description of their Rise of the FM Analyst report captures the persevering with shift in how amenities groups method operations: “Knowledge isn’t only for IT anymore. This report highlights how FMs are more and more utilizing analytics to inform the story behind facility operations. It explores how curiosity, storytelling, and information literacy are reshaping FM roles and the way groups can construct analytical capability for smarter, quicker selections.”

Organizations that digitize upkeep workflows via complete techniques acquire centralized visibility into asset efficiency, failure patterns, and upkeep effectiveness.

Automated preventive upkeep scheduling

Preventive upkeep capabilities remodel RCM implementation by automating the creation and execution of asset-specific upkeep methods. When you decide the optimum upkeep method for every asset via RCM evaluation, the platform generates personalized preventive upkeep schedules that align exactly along with your criticality assessments and failure mode evaluation.

The system mechanically creates work orders based mostly on calendar intervals, meter readings, or runtime hours relying on which set off is sensible for every asset class. For a conveyor belt requiring inspection each 4,500 bins, the platform tracks throughput and generates inspection work orders on the actual threshold. For HVAC gear serving delicate environments, it schedules filter adjustments and system checks based mostly on working hours somewhat than arbitrary month-to-month intervals.

Technicians entry full upkeep histories on the level of labor via cell purposes, guaranteeing they know precisely what was performed throughout earlier inspections, what elements have been changed, and what points have been flagged. The platform captures structured information from every upkeep exercise, constructing the asset intelligence essential to refine RCM methods over time.

Asset efficiency analytics and reporting

Asset administration platforms ship analytics that reveal failure patterns invisible in spreadsheets or paper-based techniques. The platform aggregates upkeep histories throughout an identical property at a number of places, exposing systematic points that may seem as remoted incidents when seen individually.

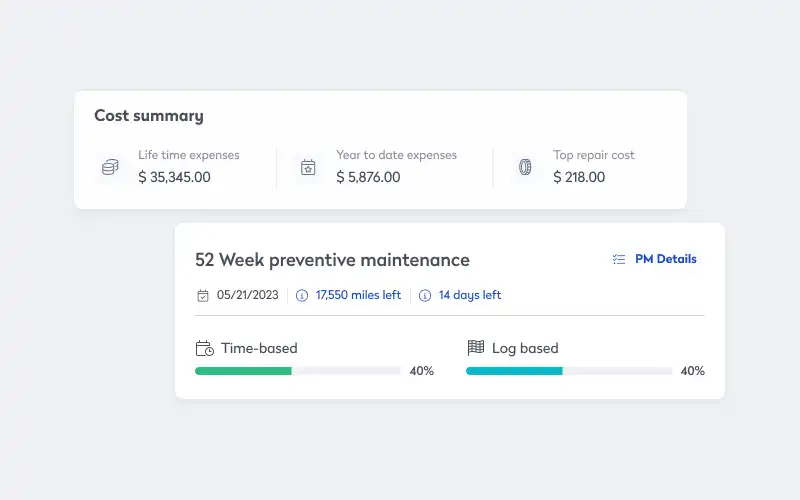

Efficiency dashboards observe key RCM metrics together with imply time between failures, upkeep prices per asset, and unplanned downtime tendencies. Services managers can filter information by asset sort, location, criticality stage, or upkeep technique to determine which approaches ship the most effective outcomes. The analytics present precisely which property eat upkeep assets disproportionately, guiding selections about when to restore versus exchange.

Automated reporting demonstrates RCM worth to organizational stakeholders by quantifying enhancements in uptime, value reductions from optimized upkeep methods, and compliance charges for preventive upkeep schedules. The info allows evidence-based conversations about upkeep investments somewhat than subjective assessments of worth.

Easy methods to implement reliability centered upkeep: 5 steps

Organizations starting RCM implementation ought to observe a structured method that builds momentum whereas demonstrating early worth. The next 5 steps create a scientific path from evaluation to outcomes.

- Consider and rank all property by criticality. Begin by evaluating property when it comes to criticality, contemplating prices for upkeep and labor, danger of harm, environmental injury, misplaced productiveness, and compliance-related fines. Keep in mind that an identical property can have totally different criticality ranges relying on their perform inside operations. Create a prioritized checklist rating property from most to least important, then focus preliminary RCM evaluation on the highest-criticality property to maximise early influence

- Conduct systematic failure mode evaluation on important property. For top-priority property, work via the seven RCM questions systematically. Collect upkeep histories, failure data, and efficiency information out of your upkeep administration platform whereas partaking upkeep technicians and operators who perceive day-to-day gear conduct. Doc failure modes, frequencies, and enterprise impacts, then determine whether or not present upkeep methods align with precise failure patterns and enterprise danger

- Develop asset-specific upkeep methods matched to failure modes. Based mostly on failure evaluation, decide the optimum upkeep method for every asset. Think about preventive upkeep with scheduled inspections and duties, predictive upkeep utilizing situation monitoring, run-to-failure for low-criticality property with minimal failure penalties, and condition-based upkeep that triggers interventions when particular thresholds are reached

- Set up key efficiency indicators and observe outcomes in opposition to baselines. Outline metrics that reveal RCM influence, together with unplanned downtime discount, imply time between failures, preventive upkeep compliance charges, upkeep value per asset, and total gear effectiveness. Measure outcomes in opposition to pre-RCM baselines to quantify enhancements and construct the enterprise case for continued funding

- Create steady enchancment cycles with common technique critiques. Schedule periodic critiques of upkeep methods, notably after vital operational adjustments, main gear failures, or shifts in enterprise priorities. Replace RCM evaluation when new failure modes emerge or when value constructions change for various upkeep approaches, guaranteeing your methods evolve along with your property and enterprise necessities

Following these sequential steps offers a framework for transitioning from conventional reactive upkeep to strategic reliability centered practices that ship measurable operational and monetary outcomes.

Begin optimizing your upkeep technique with RCM

RCM helps you progress amenities from reactive firefighting to strategic asset optimization. It’s a scientific framework that gives goal standards for matching every asset with its optimum upkeep technique whereas demonstrating tangible worth to organizational stakeholders. Organizations that efficiently implement RCM obtain measurable outcomes together with reductions in upkeep prices, decreases in unplanned downtime, and considerably prolonged asset life cycles.

With the correct expertise platform supporting data-driven decision-making, upkeep groups can transfer past producer suggestions to develop actually optimized methods tailor-made to their particular working situations and enterprise necessities.

Able to study extra about how facility administration expertise allows RCM success? Communicate with an skilled.