For fleet managers throughout industries, alternative elements choice means balancing the relative price, reliability, and availability for unique gear producer (OEM) elements and their aftermarket alternate options. Making the appropriate selections begins with software program that helps groups monitor elements efficiency, monitor failure patterns, and supply cost-benefit evaluation for strategic decision-making.

Key takeaways

- Strategic stock choices require information, not guesswork: Fleet administration software program tracks elements efficiency, life cycle prices, and stock ranges to assist select between OEM and aftermarket primarily based on complete information quite than assumptions

- Car age, part criticality, and guarantee standing drive elements choice: Use OEM elements for safety-critical programs and warranty-protected automobiles, then transition to confirmed aftermarket alternate options as fleets age and safety expires

- The aftermarket affords important financial savings however requires cautious analysis: High quality aftermarket choices exist for many functions, however monitoring efficiency information ensures reliability whereas controlling prices

Step one is knowing the variations between OEM and aftermarket elements, together with their positions within the alternative elements market and their advantages and trade-offs.

What are unique gear producer (OEM) elements?

OEM elements are the elements, each on and inside a automobile, that the corporate first produced when the automobile was new.

Previously, auto producers produced all of the elements that went into their merchandise, in order that they had been the supply of all OEM elements. Due to the complexities of trendy automotive design and intricacies of the automotive enterprise, automakers generally contract out manufacturing of some elements. In these circumstances, the corporate that produced the half beneath contract serves because the supply of OEM elements, not the automotive firm itself.

Why OEM elements are higher for fleet administration

Whenever you go along with OEM elements, the identical firm that made the originals makes OEM elements, in order that they keep the precise specs your fleet wants, eradicating an extended record of unknowns from the equation.

You by no means must ask your self if the alternative half:

- Is available in the appropriate dimension and match

- Meets the identical degree of high quality

- Delivers the identical efficiency

- Features a good guarantee

For instance, that alternative hose is the precise proper size and diameter. The brand new alternator traces up completely with the brackets, and the cables find in positions that make set up simpler with out your upkeep techs counting on on-the-spot workarounds.

As a result of the brand new half is a precise twin of the half you’re changing, you’re getting the identical degree of efficiency you noticed when the automobile was new. OEM elements additionally have a tendency to return with higher warranties backed by the businesses that produce the automobile.

As automobiles develop into extra advanced, there’s extra cause to depend on OEM. Fashionable fleet automobiles incorporate superior telematics programs, digital management items, and sensor networks that require exact compatibility. OEM elements enable you guarantee these programs proceed to speak and performance as designed, sustaining the built-in efficiency of more and more refined fleets.

Why OEM elements will not be all the time higher for fleet administration

As a supervisor in an asset-heavy trade, you’re all the time searching for methods to manage prices, and OEM elements price extra upfront. Solely wanting on the price ticket, an element by the unique producer prices greater than an analogous aftermarket half. You may be paying extra in different methods, too. Usually, OEM elements take extra time to trace down, particularly for older automobiles. Time rapidly provides to the prices. The longer a automobile sits within the storage ready on elements, the more cash you’re spending on OEM.

The crew’s time is useful, too. With the aftermarket, you usually tend to discover one or two distributors who carry all of the elements you want. With OEM, you must develop and keep a bigger community of contacts to monitor down elements. The time you spend making cellphone calls and writing emails provides up.

The counterargument right here is the whole price of possession (TCO). OEM elements, with their claims on higher match and high quality, could also be costlier solely at first.

The aftermarket costs which are simpler to seek out and cheaper to purchase can find yourself costing you extra with long-term hits to efficiency and reliability. The thought right here is you get what you pay for.

What are aftermarket elements?

As soon as about OEM elements, aftermarket elements are simple to know. They’re the alternative of OEM elements.

In lots of circumstances, aftermarket firms design their elements to suit quite a lot of makes and fashions. So, an automaker may manufacture an OEM windshield wiper blade for a particular make, mannequin, and yr. An aftermarket firm has a blade that works with that particular automobile but in addition many different makes, fashions, and years.

All these elements are widespread, and the aftermarket continues to develop quickly, projected to achieve $756 billion by 2032 at a 6% compound annual progress price.

Why aftermarket elements are higher than OEM

Aftermarket elements price much less cash than OEM elements for quite a lot of causes.

When an automaker develops a brand new half, they make investments closely into design and testing for sturdiness and security. The pricing displays these prices. The aftermarket makes a narrower funding. It solely makes particular, reverse-engineered elements unfold throughout a wider variety of makes and fashions. There’s much less for the aftermarket to recoup and extra scale towards particular person elements.

Aftermarket elements will not be simply cheaper. Generally, they’re higher. There are occasions when the aftermarket is quicker at addressing design flaws present in unique elements.

In line with trade fleet managers, aftermarket producers typically determine and repair design weaknesses extra rapidly than OEMs. A couple of years again, some pickup fleets skilled gasoline gauge issues due to how the gasoline sending unit was designed. The aftermarket had already recognized the issue and developed an improved resolution, permitting fleet managers to change to a extra dependable part.

Equally, in some circumstances aftermarket firms have re-engineered weak areas in OEM elements. When fleets skilled frequent belt tensioner failures, the bearing itself wasn’t ample to assist the load. The aftermarket responded and put in a extra sturdy bearing, which solved plenty of issues.

Why aftermarket elements may not be proper to your fleet

Aftermarket elements price much less, however they do include trade-offs. As a substitute of getting one thing purpose-built to your particular automobile, you might need to accept an element with a common match. The distinction resembles selecting between a tailored go well with that matches you completely and solely you, versus one thing purchased off the rack.

The principle drawbacks of aftermarket elements embrace:

- Much less compatibility

- Shorter doubtless life spans

- Extra restrictive warranties

As a result of the standard of supplies and workmanship can additionally be decrease, an aftermarket half could not final as lengthy. In contrast to an OEM half, aftermarket elements have much less beneficiant warranties. In some circumstances, they don’t have any.

When to make use of OEM as a substitute of aftermarket elements

As a substitute of locking your self into one or the opposite, you can greatest management prices by organising a system that will help you resolve case by case. Generally, OEM makes extra sense. Different instances, an aftermarket half delivers essentially the most worth.

Key components to guage embrace guarantee and insurance coverage necessities, part criticality, automobile age, and data-driven price evaluation.

OEM with warranties and insurance coverage

Earlier than attempting to resolve, examine to see if somebody has already made the choice for you. In some circumstances, your current warranties and insurance coverage dictate which sort of elements are attainable.

For instance, if a automobile continues to be beneath guarantee with the OEM, they’re going to make use of OEM elements. If the repairs are a part of an insurance coverage declare, the coverage might need necessities for elements.

OEM for important elements

You’ll be able to select between OEM and aftermarket primarily based on how important the half is to the automobile’s dependable and protected operation. So, if you must exchange the ground mats in a truck, you possibly can go along with an aftermarket resolution. However for the radiator, it may make extra sense to make use of OEM.

Keep in mind, OEM prices extra at first, however you usually tend to lower your expenses in the long term due to higher efficiency and reliability. For non-critical elements, that’s by no means going to be a lot of a problem. However for the elements that maintain your fleet on the street, TCO is commonly decrease with OEM.

Aftermarket for older automobiles

As your fleet ages, it makes sense to step by step swap to aftermarket elements.

One of many benefits of OEM elements is that you simply belief them to return your automobiles to like-new efficiency. In idea, your alternative gasoline pump has that a part of the engine working similar to it did when it was recent off the meeting line. However is it value the associated fee when the remainder of the engine is already exhibiting its age?

Even should you might see an actual increase in efficiency from that outdated engine, it’s not going to be round for lengthy. There’s no cause to make use of a brand new half that comes with a five-year guarantee when the automobile has solely two extra years of helpful life left in it.

Ultimately, even should you determined it was definitely worth the cash to make use of OEM on older automobiles, the market may make it not possible. The older your fleet will get, the tougher it’s to seek out OEM elements. Even if you do, the time it takes to seek out and ship them means extra downtime.

How fleet administration software program helps smarter elements stock administration

Fleet managers who reach balancing high quality and value take a scientific, data-driven method to elements choices. Fashionable fleet administration software program places complete information at your fingertips, letting you progress past guesswork and outdated spreadsheets.

Defining the steps in broad strokes, you can begin by categorizing fleet elements into three tiers.

- Tier one: Include safety-critical and warranty-protected programs that require OEM elements

- Tier two: Covers essential programs the place high-quality aftermarket alternate options have confirmed dependable

- Tier three: Encompasses commodity elements the place aftermarket choices persistently ship ample efficiency at important financial savings

From there, monitor efficiency metrics for every class. Monitor failure charges, alternative frequency, labor hours for set up, and whole price per mile for various half sorts. When six months or a yr of information accumulates, patterns emerge that information buying technique.

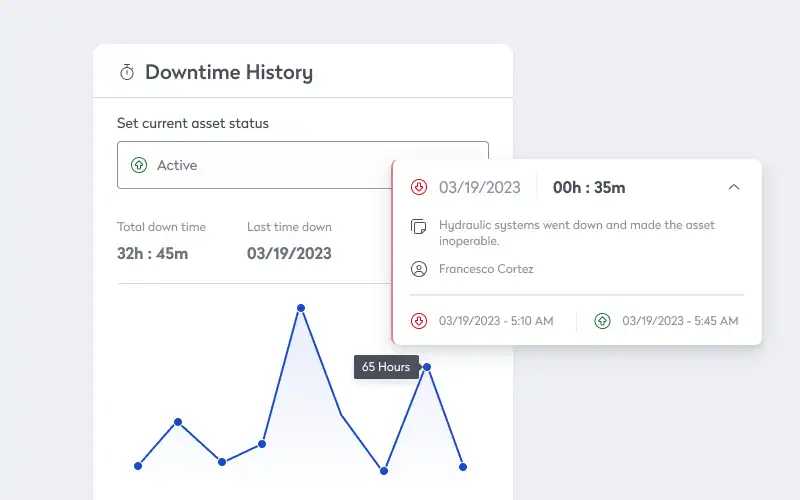

Observe elements efficiency and life cycle information

With asset administration analytics, analyze elements efficiency throughout your entire fleet. Observe which elements fail most steadily, how lengthy completely different elements final, and whether or not OEM or aftermarket replacements present higher worth for particular functions.

Construct a complete efficiency database by monitoring:

- Failure charges for every part kind

- Common service life earlier than alternative

- Set up labor hours and complexity

- Whole price per mile for various half sorts

- Guarantee declare frequency by producer

When the info reveals {that a} explicit aftermarket brake pad persistently lasts for under 85% of the time because the OEM model however prices 60% much less, the maths turns into clear. The aftermarket possibility delivers higher worth for non-critical elements, particularly when financial savings multiply throughout a big fleet.

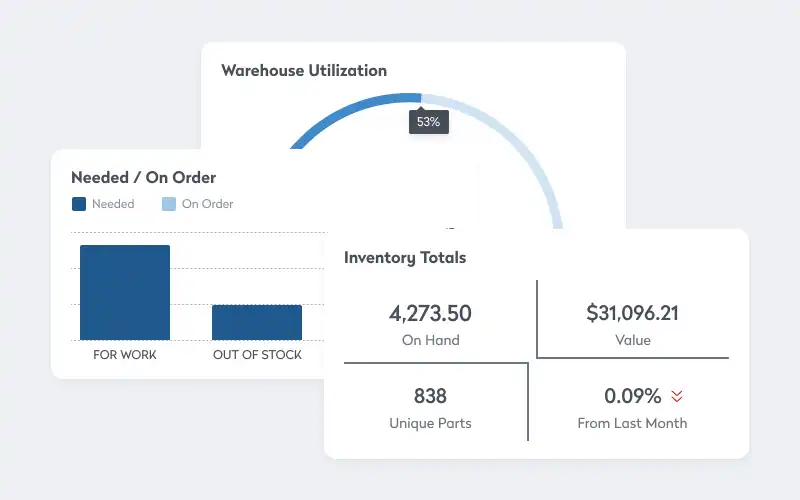

Optimize stock primarily based on actual utilization patterns

Elements stock administration instruments assist keep the appropriate stability of OEM and aftermarket elements. Observe utilization patterns and alter inventory ranges primarily based on precise consumption information as a substitute of guesswork or outdated forecasts.

Analyze stock information to decide:

- Which OEM elements to inventory for important, time-sensitive repairs

- Which aftermarket alternate options transfer rapidly sufficient to justify bulk orders

- Optimum reorder factors primarily based on precise consumption charges

- Seasonal variation in elements demand throughout the fleet

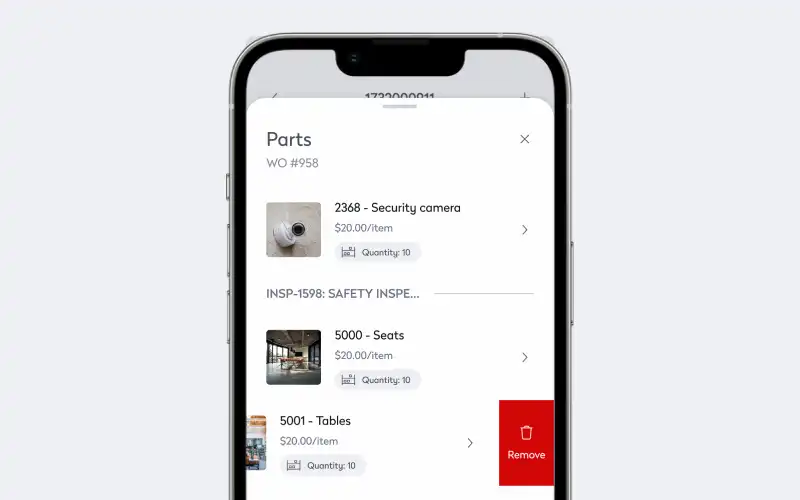

With real-time stock monitoring and barcode scanning, you all the time know what’s obtainable. When a technician wants an element, instantly see whether or not it’s in inventory, the place it’s positioned, and whether or not an OEM or aftermarket model is out there. Streamline ordering by way of built-in vendor administration, making it simple to rapidly supply OEM elements when wanted whereas sustaining relationships with dependable aftermarket suppliers for routine replacements.

Schedule preventive upkeep strategically

Preventive upkeep scheduling capabilities rework how fleet managers plan repairs and handle elements availability. Construct a proactive upkeep technique that aligns elements procurement with scheduled service home windows, scheduling upkeep when aftermarket elements arrive quite than paying premium costs for rush OEM deliveries.

- Develop a strategic upkeep calendar by coordinating:

- Scheduled service intervals with elements lead instances

- Aftermarket half supply schedules with obtainable upkeep home windows

- OEM part alternative with manufacturer-recommended intervals

- Bulk upkeep operations to maximise technician effectivity

Observe lead instances for each OEM and aftermarket suppliers meticulously. When information reveals {that a} particular aftermarket provider persistently delivers brake rotors in three days whereas OEM variations take two weeks, schedule brake service to accommodate the sooner, more cost effective possibility. Construct provider efficiency into upkeep planning, avoiding expensive automobile downtime by aligning service home windows with lifelike elements availability.

Configure automated upkeep schedules that guarantee important OEM elements get changed at manufacturer-recommended intervals. Keep guarantee compliance and security requirements by by no means extending service intervals on safety-critical programs. For much less important programs, leverage flexibility to optimize prices. When aftermarket elements show dependable by way of efficiency monitoring, lengthen alternative intervals primarily based on precise put on information quite than conservative OEM suggestions.

Use circumstances, together with associated options and concrete steps, for deciding between OEM and aftermarket elements

By combining particular efficiency analytics, real-time stock monitoring, and built-in vendor administration capabilities, fleet managers throughout industries could make data-driven choices that scale back upkeep prices, optimize elements stock ranges, and remove expensive emergency repairs whereas sustaining gear reliability and security compliance.

Building fleet supervisor leverages elements efficiency analytics to chop upkeep prices

Think about you handle a building fleet of 47 excavators, bulldozers, and dump vans scattered throughout three energetic job websites. Final quarter, your upkeep finances elevated by 30%, however conventional spreadsheet monitoring couldn’t determine the foundation trigger.

Your mechanics continued ordering alternative hydraulic hoses at inconsistent intervals. Some gear required new hoses each six months whereas similar machines operated for eighteen months between failures. You wanted concrete information to know these efficiency discrepancies.

You deploy asset administration analytics to construct a complete efficiency database that tracks failure charges, common service life, set up labor hours, and whole price per working hour for completely different part sorts. Each time your mechanics exchange an element, you may have them log it by way of barcode scanning, robotically capturing set up dates, labor prices, and guarantee data.

Inside three months, you analyze the info and uncover that aftermarket hydraulic hoses fail at practically twice the speed of OEM elements however price 65% much less. Drilling deeper into the segmented information, you uncover a important distinction: gear working within the quarry’s abrasive atmosphere experiences aftermarket hose failures after solely 4 months, whereas similar aftermarket hoses on dump vans operating paved routes carry out reliably for fourteen months.

You then use built-in price administration instruments to calculate whole price per mile for every situation, proving that OEM hoses ship superior worth in harsh environments regardless of greater upfront pricing.

From there, you configure automated guidelines inside the asset life cycle monitoring system that suggest half sorts primarily based on particular automobile functions, utilization patterns, and historic efficiency information. Tools assigned to abrasive quarry work receives OEM hoses robotically, whereas road-running vans default to cost-effective aftermarket alternate options.

You additionally arrange computerized alerts for when automobiles transition from guarantee protection to impartial upkeep, enabling you to shift from obligatory OEM elements to confirmed aftermarket choices at exactly the optimum second.

As a result of you’re documenting circumstances the place aftermarket elements exceed OEM longevity in particular functions, you possibly can negotiate quantity pricing with suppliers who persistently ship high quality elements. Over the subsequent six months, your upkeep finances decreases whereas gear reliability improves.

Municipal fleet optimizes stock administration and reduces elements inventory

Now you’re overseeing 130 automobiles for a municipal authorities, together with police cruisers, sanitation vans, hearth engines, and normal service sedans, however there’re a constant mismatch between what you may have and what the fleet wants as a result of your predecessor managed stock primarily based on instinct and generic producer suggestions designed for fleets with fully completely different operational profiles.

For instance, the elements room comprises ten circumstances of brake rotors for Crown Victorias that town retired three years in the past and a single oil filter for a specialised hearth truck, ordered eighteen months in the past at premium rush pricing, nonetheless unused in its packaging. In the meantime, mechanics spend hours every week ready for frequent elements that ought to be available.

So, you implement a contemporary elements stock administration system and instantly begin analyzing consumption information to disclose distinct patterns invisible in annual abstract stories. You uncover that police cruisers eat brake pads at thrice the civilian automobile price as a result of fixed idling and fast acceleration patterns. Sanitation vans require air filter alternative each six weeks throughout fall leaf season however keep the identical filters for 4 months throughout summer season operations.

You configure the cloud-based platform to investigate historic utilization information and set minimal and most inventory ranges primarily based on precise consumption charges quite than arbitrary estimates.

For top-velocity elements like aftermarket oil filters, you utilize the info to justify bulk ordering that captures price financial savings by way of quantity pricing. For slow-moving specialty elements required for hearth equipment, you set up expedited ordering protocols with OEM suppliers as a substitute of tying up capital in hardly ever used elements that danger obsolescence.

You additionally leverage the unified vendor administration module to create scorecards that objectively monitor supply instances, high quality points, and pricing competitiveness throughout all suppliers. You analyze the info and uncover that a bigger aftermarket provider averages eleven-day supply instances with three incorrect shipments final quarter, incomes them secondary vendor standing regardless of preferential remedy from metropolis council. A smaller provider persistently delivers correct orders in 4 days with zero errors, so that you award them most well-liked standing and extra stock commitments.

You additionally use real-time stock monitoring to decide which OEM elements to inventory for important, time-sensitive repairs, and which aftermarket alternate options transfer rapidly sufficient to justify bulk orders.

To enhance general information seize, you additionally equip your technicians with barcode scanning integration to allow them to immediately confirm elements availability, location, and whether or not OEM or aftermarket variations exist in inventory. Elements stock shrinks whereas elements availability for precise upkeep wants improves considerably.

Supply fleet supervisor eliminates emergency repairs with strategic preventive upkeep scheduling

Think about you’re in cost of logistics for a regional supply firm with 83 vans working beneath tight supply schedules. Each automobile present process unplanned upkeep represents $400 in day by day misplaced income.

Yesterday, three vans required unscheduled brake service when mechanics found worn rotors throughout routine inspections. Your OEM elements distributor initially promised a two-day supply however known as this morning to report a five-day delay as a result of provider shortages. These vans stay idle whereas dispatch scrambles to cowl routes with backup automobiles already working past beneficial service intervals.

You implement a complete preventive upkeep scheduling platform and instantly set it as much as robotically monitor provider lead instances. You uncover that your most well-liked aftermarket brake provider maintains a constant 72-hour supply window whereas delivering 55% price financial savings in comparison with OEM pricing.

You configure the software program to monitor brake put on information throughout your entire fleet by way of asset administration analytics, permitting you to foretell service necessities three weeks upfront primarily based on precise utilization patterns and part put on charges.

For subsequent Tuesday’s scheduled brake service masking 5 vans, you place aftermarket elements orders immediately by way of built-in vendor administration, guaranteeing elements arrive Friday with time to confirm high quality earlier than the service window. You then schedule the vans to enter the bay Monday night, obtain new brakes Tuesday morning, and return to revenue-generating routes by afternoon.

You additionally leverage the trendy fleet administration platform to deal with extra advanced life cycle necessities past routine upkeep.

For instance, you use automated upkeep schedules to make sure important OEM elements like steering assemblies attain manufacturer-recommended alternative intervals at 90,000 miles, sustaining insurance coverage protection necessities and security compliance.

You configure the centralized system to generate work orders robotically, hyperlink them to pre-verified elements stock, and assign technicians with applicable certifications.

For much less important programs like air-con, you analyze your efficiency monitoring database and uncover that aftermarket compressors match OEM longevity at half the associated fee. So, you lengthen alternative intervals from conservative producer suggestions to data-driven schedules primarily based on precise put on patterns noticed throughout your particular working circumstances.

Now as a substitute of automobiles sitting idle awaiting elements, you align scheduled upkeep home windows with confirmed elements availability and technician capability, optimizing each asset utilization and upkeep effectivity.

Stability OEM and aftermarket elements with data-driven decision-making

The selection between OEM and aftermarket elements represents a strategic resolution that impacts fleet efficiency, reliability, and prices. OEM elements ship exact match and assured efficiency however command greater costs and longer lead instances. Aftermarket alternate options provide price financial savings and broader availability, although high quality varies throughout producers.

Fashionable fleet administration software program eliminates the guesswork from this resolution by offering complete efficiency analytics, real-time price monitoring, and historic information throughout your total fleet. As a substitute of counting on producer claims or trade generalizations, you possibly can analyze precise failure charges, service life, and whole price per mile for each OEM and aftermarket elements in your particular operational atmosphere.

Fashionable options ship insights into elements and other people. Built-in vendor administration instruments allow you to examine provider reliability, supply instances, and pricing competitiveness objectively, whereas automated stock programs make sure you keep optimum inventory ranges for each half sorts primarily based on precise consumption patterns.

Armed with a data-driven method, you possibly can optimize the stability between reliability, availability, and expense throughout your total operation.