Work orders are the fundamental constructing blocks of a profitable upkeep operation. Upkeep leads use them to regulate assets effectively, whereas technicians must them know what to do. And not using a clear prioritization technique, nevertheless, groups waste time on work that doesn’t assist them forestall expensive failures and help enterprise objectives. Prioritization is what turns a listing of requests into an efficient, actionable plan.

A digital upkeep answer simplifies and strengthens prioritization by centralizing asset knowledge, automating request consumption, and making use of guidelines to rank duties primarily based on urgency and enterprise impression.

Key takeaways

- Implementing a piece order hierarchy helps forestall small issues from escalating into expensive failures by tackling high-risk or high-impact points first

- A precedence matrix evaluating asset criticality and operational threat permits upkeep groups to make knowledgeable choices about which work orders to finish first

- Fashionable upkeep options with options like centralized work order administration, cellular entry, complete dashboards, and built-in security monitoring help efficient work order prioritization

Upkeep and restore prices stay a serious operational expense. In some manufacturing environments, they account for as much as 20% of whole working prices. Implementing a piece order hierarchy, the place the workforce tackles high-risk or high-impact points first, helps forestall small issues from escalating into expensive failures and intensive repairs.

By constructing a system that ranks work orders primarily based on urgency, asset criticality, and threat, upkeep managers could make higher use of technician time, scale back downtime, and maintain operations working easily.

What is figure order prioritization?

Each group has upkeep duties they should full to maintain operations working, however not all work orders carry the identical degree of significance. Requests differ in urgency, complexity, and general impression. The method of evaluating them and deciding the order the workforce ought to full them is figure order prioritization.

Work order prioritization is the framework your workforce makes use of to find out which duties to handle first. It helps align upkeep actions with enterprise objectives by specializing in the work that has the best impression on uptime, security, and value management. It’s an method that ensures the division has its technicians spending time the place it issues most.

What are the challenges of outdated work order prioritization?

Poor work order administration can quietly drain assets and inflate prices, particularly with no digital system to help prioritization. When the division should assign duties manually or attempt to monitor them throughout disconnected instruments, upkeep groups usually spend time on low-impact jobs whereas important points go unresolved. The misallocation of technician time and ability undermines productiveness and drives up bills.

With out centralized knowledge and automatic workflows, services are likely to default to reactive upkeep, an costly method. However with no system to rank duties by urgency and impression, it’s troublesome to make the shift to proactive upkeep. The workforce stays trapped with longer downtimes, emergency labor prices, and elevated put on on belongings.

How can upkeep managers create a piece order prioritization program?

And not using a clear system for rating work orders, productiveness suffers, and prices rise. A structured prioritization program helps upkeep groups deal with what issues most.

Begin with security

You need to at all times deal with safety-related work orders as excessive precedence, even when they don’t immediately have an effect on manufacturing. For instance, a broken guard rail on a machine might not cease operations, but it surely poses a critical threat to operators.

OSHA violations are expensive and disruptive. In fiscal yr 2024, the highest 10 most ceaselessly cited requirements included fall safety, hazard communication, lockout/tagout procedures, and machine guarding.

These violations additionally contribute to office accidents, unplanned downtime, and long-term reputational harm.

Use a precedence matrix

A precedence matrix helps you consider work orders primarily based on two key dimensions: asset criticality and operational threat. A structured method removes guesswork and ensures you care for a very powerful duties first.

Examples of asset criticality, from excessive to low, embody:

- Well being and security compromised

- Major manufacturing down

- Secondary or help methods down

- Non-essential manufacturing affected

- Employee consolation impacted

By separating asset criticality from operational threat, you’ll be able to consider every work order from a number of angles, which helps guarantee pressing duties tied to security or manufacturing aren’t delayed by lower-impact requests.

Examples of operational threat, from excessive to low, embody:

- Quick security menace

- Quick manufacturing loss

- Potential manufacturing loss

- Danger of regulatory non-compliance

- Preventive upkeep

- Common enhancements or optimizations

By assigning scores to each asset criticality and operational threat, groups could make extra knowledgeable choices about which work orders to finish first, creating consistency within the prioritization course of and serving to make sure that high-impact duties are by no means delayed by lower-priority requests.

Prepare the groups

Asset operators usually create the preliminary work orders, so that they want clear steering on how one can assess urgency. Coaching workers to make use of the matrix ensures constant prioritization and helps technicians deal with high-impact duties.

Managers play a key position in last scheduling, although, as a result of they’ll think about technician availability, stock ranges, and operational context. With visibility throughout the plant, you may make knowledgeable changes that help general effectivity.

Implement accountability

Even with coaching, some technicians might full work orders out of sequence or depend on instinct, resulting in delays, wasted labor, and unreliable knowledge.

Auditing work orders helps managers determine patterns and reinforce greatest practices. A contemporary upkeep platform means that you can assign duties, monitor completion, and evaluation efficiency, making it simpler to identify inconsistencies and supply focused teaching.

How does a contemporary upkeep platform help a piece order prioritization program?

Digital transformation is important for constructing a scalable, constant work order prioritization technique. Fashionable upkeep platforms provide purpose-built options that assist groups triage requests, assign duties effectively, and guarantee technicians do probably the most important work first.

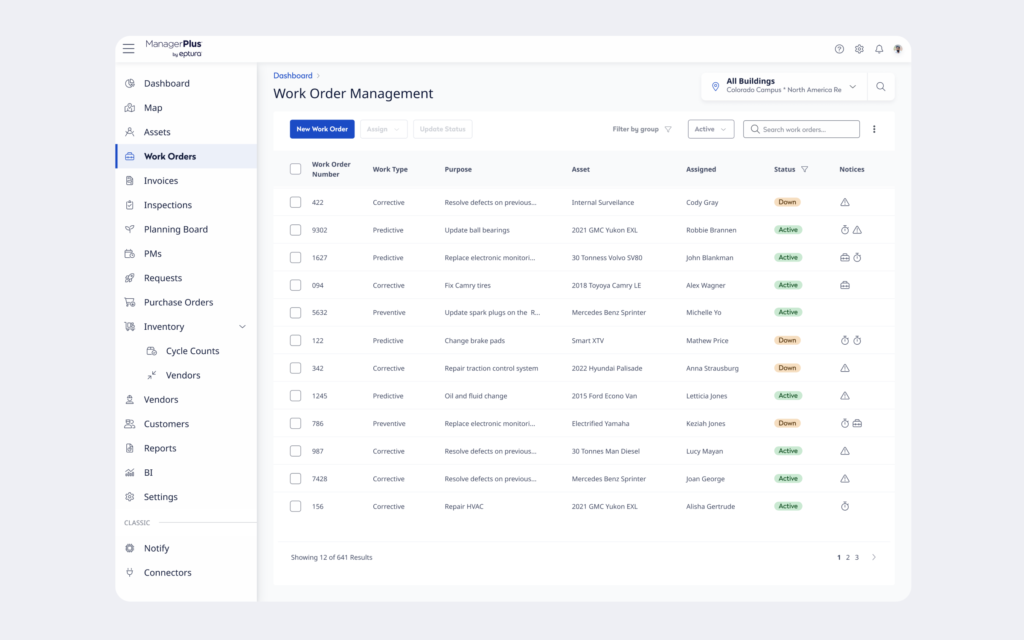

Centralized work order administration

A centralized system permits upkeep groups to handle all incoming requests from a single interface. You’ll be able to kind and filter work orders by precedence degree, asset kind, location, and due date. Improved visibility makes it simpler to determine which duties require quick consideration and which will be scheduled later. Many platforms additionally help automated routing guidelines, so work orders tied to security, compliance, or high-risk belongings are flagged and escalated robotically, reducing handbook triage and making certain consistency throughout groups.

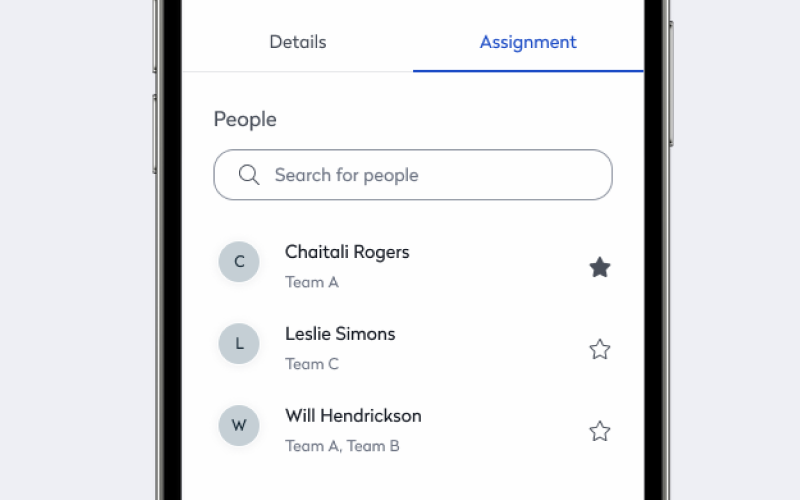

Cell entry for technicians

Cell upkeep apps give technicians real-time entry to their assigned work orders, full with precedence indicators, asset historical past, and step-by-step directions. Technicians can replace standing, log notes, and shut out duties immediately from their gadgets, which helps scale back delays and improves knowledge accuracy. Some apps additionally embody barcode scanning and photograph documentation, permitting technicians to confirm work and seize points on the spot. The extent of entry ensures the workforce tackles high-priority duties rapidly, even when unfold throughout a number of websites.

Built-in security and compliance monitoring

You’ll be able to arrange the system to robotically flag work orders tied to security inspections or regulatory duties. In reality, fashionable platforms usually embody built-in compliance instruments resembling inspection checklists, audit trails, and documentation templates. The mixing makes it simpler to determine and prioritize safety-related duties and helps make sure the workforce doesn’t overlook compliance work.

It additionally simplifies reporting for inner critiques and exterior audits, reinforcing the significance of security within the prioritization course of.

Complete dashboards for upkeep leads, managers, and supervisors

Dashboards present supervisors with a real-time overview of open work orders, technician availability, and asset situations. Visibility helps managers make knowledgeable choices about which duties to prioritize and when to regulate schedules. For instance, if a technician is already on website and a high-priority job is submitted, the dashboard makes it simple to reassign work primarily based on location and ability set. Dashboards additionally assist monitor completion charges and determine bottlenecks, which helps steady enchancment in prioritization methods.

By combining these options, digital platforms remodel work order prioritization from a handbook, reactive course of right into a structured, data-driven workflow. Upkeep groups acquire the instruments they should deal with the suitable duties on the proper time, serving to you scale back downtime, enhance security, and management prices.

Prioritizing success with stronger work order administration

By implementing a structured work order prioritization technique, upkeep groups can enhance operational effectivity, scale back prices, and improve general security. Leveraging fashionable upkeep options with superior options like routing, cellular entry, and built-in compliance monitoring permits organizations to rework their upkeep operations from reactive to proactive, data-driven workflows, serving to scale back downtime and enhance security whereas controlling prices and supporting enterprise objectives successfully.