Misaligned upkeep in manufacturing operations drains productiveness and profitability. Merely adopting “good upkeep” isn’t sufficient, although. The answer is implementing the correct mix of preventive and predictive triggers that match your gear, working situations, and funds realities.

Probably the most profitable mid-market producers don’t select between preventive upkeep (PM) and predictive upkeep (PdM). They sequence each strategically, constructing preventive self-discipline first earlier than introducing selective predictive capabilities the place they ship the very best ROI. With unplanned downtime costing Fortune International 500 firms 11% of yearly turnover, organizations want a pragmatic, phased strategy to upkeep modernization that permits them to use lessons-learned whereas constructing on earlier successes.

Key takeaways

- Sequence PM earlier than PdM for optimum influence: Grasp preventive upkeep fundamentals first, reaching greater compliance charges earlier than introducing predictive capabilities. A sequenced strategy creates the info basis and crew habits crucial for profitable predictive upkeep scaling

- Use condition-based triggers strategically: Apply preventive upkeep to safety-critical techniques and gear with secure working situations, whereas reserving predictive upkeep for growing older crucial belongings, high-downtime-cost gear, and equipment with variable working situations

- Show worth via targeted pilots: Leverage your upkeep administration platform’s reporting instruments to doc diminished downtime prices, decrease emergency restore bills, and improved manufacturing throughput, constructing the enterprise case for broader deployment

Each manufacturing facility faces its personal particular set of operational circumstances, however these rules can assist you create a practical, tailor-made roadmap for advancing reliability maturity.

What retains manufacturing vegetation in reactive upkeep

Many mid-market manufacturing vegetation function in a perpetual state of reactive upkeep regardless of management’s want for extra proactive approaches. Producers anticipate enter prices to extend by a mean of 5.4% over the subsequent yr, whereas growing older gear and workforce challenges amplify operational pressures, in line with the Nationwide Affiliation of Producers’ 2025 Manufacturing Outlook.

Manufacturing services now lose a mean of 25 hours month-to-month to unplanned downtime, with the ABB Worth of Reliability report discovering that two-thirds of firms cope with unplanned downtime not less than as soon as a month, at a price of $125,000 per hour. Imply time to restore has elevated from 49 minutes to 81 minutes, pushed largely by provide chain delays and a widening abilities hole.

Shawn Morgal, vice chairman of services administration and operations and upkeep at The Constructing Folks, defined the significance of skilled technicians to total success in a Asset Champion podcast episode.

“You may have the most effective facility supervisor overseeing any constructing in any location, however you actually need to grasp and admire that it’s the boots which are on the bottom, the arms which are turning the wrenches, the employees that’s maintaining these services conditioned and clear and secure and accessible.”

Construct preventive upkeep self-discipline first

Sturdy PM self-discipline creates the inspiration you want for profitable PdM implementation whereas delivering rapid reliability enhancements. Organizations with mature preventive upkeep packages expertise considerably diminished downtime and prolonged asset life cycles, in line with Eptura’s 2025 Office Index. Deloitte analysis confirms these findings, displaying predictive upkeep can scale back upkeep prices as much as 25% and enhance uptime by 10% to twenty%.

Implementing and working a PM program is a multistep course of that consists of:

- Establishing constant upkeep routes and frequencies: Work via your asset stock systematically, starting with gear that helps crucial manufacturing processes. A meals processing plant would possibly prioritize mixing gear and packaging traces, whereas an automotive elements producer focuses on stamping presses and welding robots. Doc particular inspection factors, required instruments, and acceptance standards that outline correct preventive upkeep for every asset class

- Rating belongings utilizing risk-based criticality: Take into account a number of components together with alternative value, manufacturing influence if failed, security dangers, environmental penalties, and present asset situation. The first CNC machine in your manufacturing flooring carries greater criticality than a backup unit, simply as the primary injection molding press calls for extra consideration than auxiliary gear.

- Creating standardized process libraries: Develop procedures organized by asset kind and upkeep frequency. Standardized procedures guarantee consistency no matter which technician performs the work, whereas enabling correct time estimates for scheduling and capability planning. A plastics producer managing a number of manufacturing traces can apply the identical extrusion gear guidelines throughout machines, adjusting just for model-specific particulars

- Monitoring compliance religiously: Deal with PM compliance as a elementary crew efficiency metric that predicts future reliability. Your upkeep platform can present you precisely which deliberate duties have been accomplished on schedule and which require consideration

In an episode of the Asset Champion podcast, Cameron Christensen, director of asset administration for services operations at Princeton College, careworn the necessity to perceive the relationship between technique and expertise when implementing new packages. Whereas carefully related, they’re additionally completely different.

“Expertise just isn’t the technique. It’s an accelerator of technique. It’s a vital piece of our technique, nevertheless it’s not the technique itself.”

Implement upkeep software program to allow data-driven reliability

As soon as your preventive upkeep self-discipline reaches constant compliance ranges, you have the steadiness essential to introduce predictive upkeep administration.

Right here, the important thing is leveraging expertise to determine high-impact purposes the place condition-based triggers ship clear benefits over time-based approaches.

Introduce predictive triggers with situation monitoring

Focus your predictive investments on belongings the place failures carry important operational or monetary penalties. Tools supporting steady manufacturing processes, belongings with excessive restore or alternative prices, and equipment the place failures create security dangers or environmental incidents justify the incremental value of situation monitoring.

For a pharmaceutical producer, this would possibly imply crucial pill presses and coating gear, whereas at a steel fabrication operation, it consists of major slicing and forming machines the place failures halt complete manufacturing cells.

Vibration evaluation offers your most accessible entry level. Rotating gear together with motors, pumps, gearboxes, and followers can all profit from vibration monitoring that detects bearing put on, misalignment, and imbalance earlier than catastrophic failure happens. Moveable vibration analyzers require minimal funding whereas enabling your technicians to set up baseline readings and monitor degradation tendencies over time.

For instance, a beverage bottling plant can use handheld analyzers to verify conveyor motors throughout weekly rounds. Figuring out creating issues earlier than a midnight breakdown halts the filling line.

Cycle counters or runtime meters allow condition-based upkeep for gear the place utilization varies considerably. A stamping press that operates intermittently based mostly on manufacturing schedules advantages extra from upkeep triggered after particular utilization thresholds than from arbitrary time intervals. Set up easy counters that combine together with your upkeep administration platform to generate work orders robotically when utilization thresholds are reached.

For instance, a packaging gear producer can monitor precise cycle counts on every machine quite than calendar time, making certain upkeep aligns with actual put on patterns.

Create related work orders and cellular entry

Related work orders kind the inspiration of efficient upkeep knowledge circulate. Your technicians ought to log each upkeep exercise via the upkeep administration platform, capturing work carried out, time invested, elements consumed, and asset situations noticed. The self-discipline of constant knowledge entry proves as vital because the expertise platform itself.

You’ll be able to construct your technician logging habits via clear expectations, streamlined cellular interfaces, and common knowledge high quality critiques.

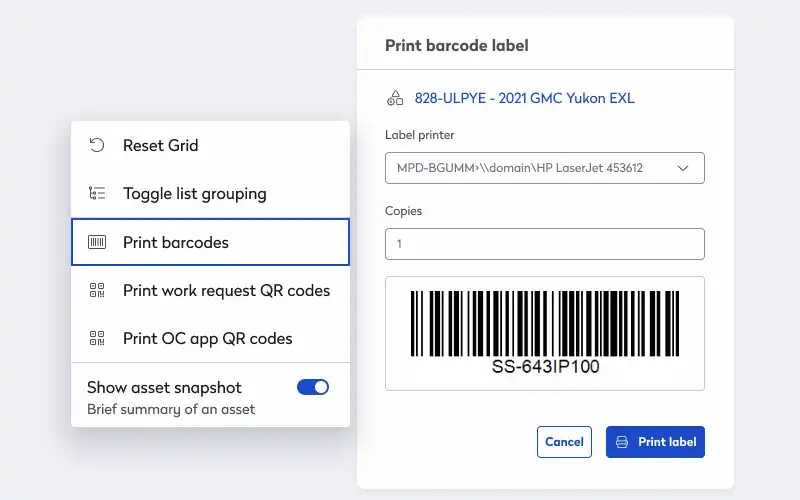

Trendy asset administration platforms present barcode scanning capabilities that allow your technicians to shortly entry crucial gear knowledge, open work orders, upkeep historical past, photographs, manuals, and different paperwork. When your technician arrives at a malfunctioning injection molding machine, they will scan the gear barcode with their cellular machine and immediately see the final three repairs, present elements stock, and OEM troubleshooting guides.

Consolidate your asset data right into a single platform that connects upkeep histories with procurement knowledge, working specs, and efficiency metrics. When your technicians reply to gear points, they want rapid entry to earlier restore histories, elements availability, producer documentation, and working parameters with out looking out via a number of disconnected techniques.

For instance, a chemical processing plant managing reactor vessels throughout manufacturing areas can view each upkeep occasion for comparable gear, figuring out whether or not a recurring difficulty impacts one unit or represents a systemic downside requiring engineering intervention.

Monitor efficiency with dashboards and automatic stories

Set up key efficiency indicators that measure your upkeep program effectiveness via automated reporting capabilities. Monitor imply time between failures by asset class, upkeep value per unit of manufacturing, preventive upkeep compliance charges, and unplanned downtime tendencies. Evaluation these metrics month-to-month together with your upkeep crew, investigating destructive tendencies and celebrating enhancements.

Your upkeep administration platform dashboards present real-time visibility into upkeep operations. A packaging movie producer would possibly uncover via dashboard analytics that one manufacturing line experiences twice as many emergency repairs as comparable traces, triggering investigation into whether or not operator coaching, gear age, or course of parameters contribute to elevated failure charges. The system robotically tracks complete upkeep spend by asset, enabling data-driven repair-versus-replace choices.

Then use your consolidated knowledge to refine upkeep methods constantly. When an asset class reveals growing failure charges regardless of constant PM compliance, the info indicators your want for technique adjustment. Maybe your PM intervals require tightening, or condition-based triggers would show more practical than time-based schedules.

When to make use of PM vs PdM: a sensible set off matrix

Completely different upkeep methods swimsuit completely different gear varieties, working situations, and enterprise contexts. Understanding when to use preventive versus predictive approaches permits optimum useful resource allocation.

Preventive upkeep triggers can work greatest for:

- Producer-recommended intervals: Tools the place OEM steerage offers dependable scheduling path

- Security-critical techniques: Emergency lighting, fireplace suppression techniques, and fall safety units requiring common inspection no matter situation

- Low-cost inspections: Belongings the place inspection duties value considerably lower than failure penalties

- Secure working situations: Tools working underneath constant environmental and operational parameters

- Predictive upkeep triggers can ship higher outcomes for:

- Ageing crucial belongings: Tools the place remaining helpful life varies based mostly on working stress and collected put on

- Excessive downtime prices: Belongings the place failures justify monitoring funding via substantial operational influence

- Variable working situations: Tools subjected to altering masses, speeds, or environmental components

- Measurable situation indicators: Rotating gear, thermal patterns, or different parameters with clear degradation indicators

The optimum set off technique evolves as gear ages, working situations change, and upkeep capabilities mature. So, be sure that to overview and alter set off assignments on a set schedule, utilizing collected efficiency knowledge out of your digital upkeep administration platform to refine your strategy constantly.

Chart your path to proactive upkeep

Mid-market manufacturing leaders face respectable funds constraints that make wholesale, all-at-once upkeep transformation unrealistic. The answer is sequencing: grasp preventive self-discipline first, then introduce predictive capabilities the place they ship the very best ROI. It’s an strategy that delivers measurable reliability enhancements with out requiring massive upfront investments.

Organizations that construct sturdy PM fundamentals create the info basis and crew habits crucial for profitable PdM scaling. Targeted pilots show worth shortly, constructing organizational confidence whereas demonstrating tangible returns. The mix of improved uptime, diminished upkeep prices, and prolonged asset life cycles creates a self-funding enchancment cycle that advances your reliability maturity over time.

Able to construct your upkeep roadmap? Get sensible implementation steps and greatest practices in our full preventive upkeep information.