Key Takeaways

- Sensible manufacturing makes use of Synthetic Intelligence (AI), the commercial Web of Issues (IIoT), digital twins, and robotics to resolve pressing challenges like labor shortages, rising prices, and high quality management.

- Not like conventional automation, good manufacturing creates a totally related ecosystem the place knowledge drives real-time decision-making and effectivity.

- Integrating these applied sciences allows predictive upkeep, sustainable manufacturing, and hyper-customized outputs—all whereas decreasing waste.

- Corporations like Boeing exhibit how good automation and lean practices can considerably improve manufacturing velocity, security, and precision.

- To remain aggressive, U.S. producers should put money into digital infrastructure and upskill their workforce to totally unlock the potential of good manufacturing.

The way forward for American manufacturing is sensible. To compete in an more and more international market, American producers should undertake clever applied sciences that may anticipate, modify, and hyper-customize manufacturing in actual time. These improvements don’t simply deliver effectivity—they create new worth and unlock the potential to re-shore crucial industries.

Sensible manufacturing isn’t nearly automation—it’s about ecosystems. Methods that talk to one another. Information that informs each transfer. Machines that make manufacturing sooner, cleaner, and extra adaptable. These developments are arriving simply in time. Producers at this time face strain to scale back prices, handle labor shortages, meet sustainability targets, and preserve high quality—all whereas remaining globally aggressive.

With applied sciences like AI, the IIoT, digital twins, and robotics, good manufacturing affords a strategic path ahead. And past addressing at this time’s challenges, it positions U.S. business to deliver extra manufacturing again residence—and construct a extra resilient, responsive future.

What is sensible manufacturing?

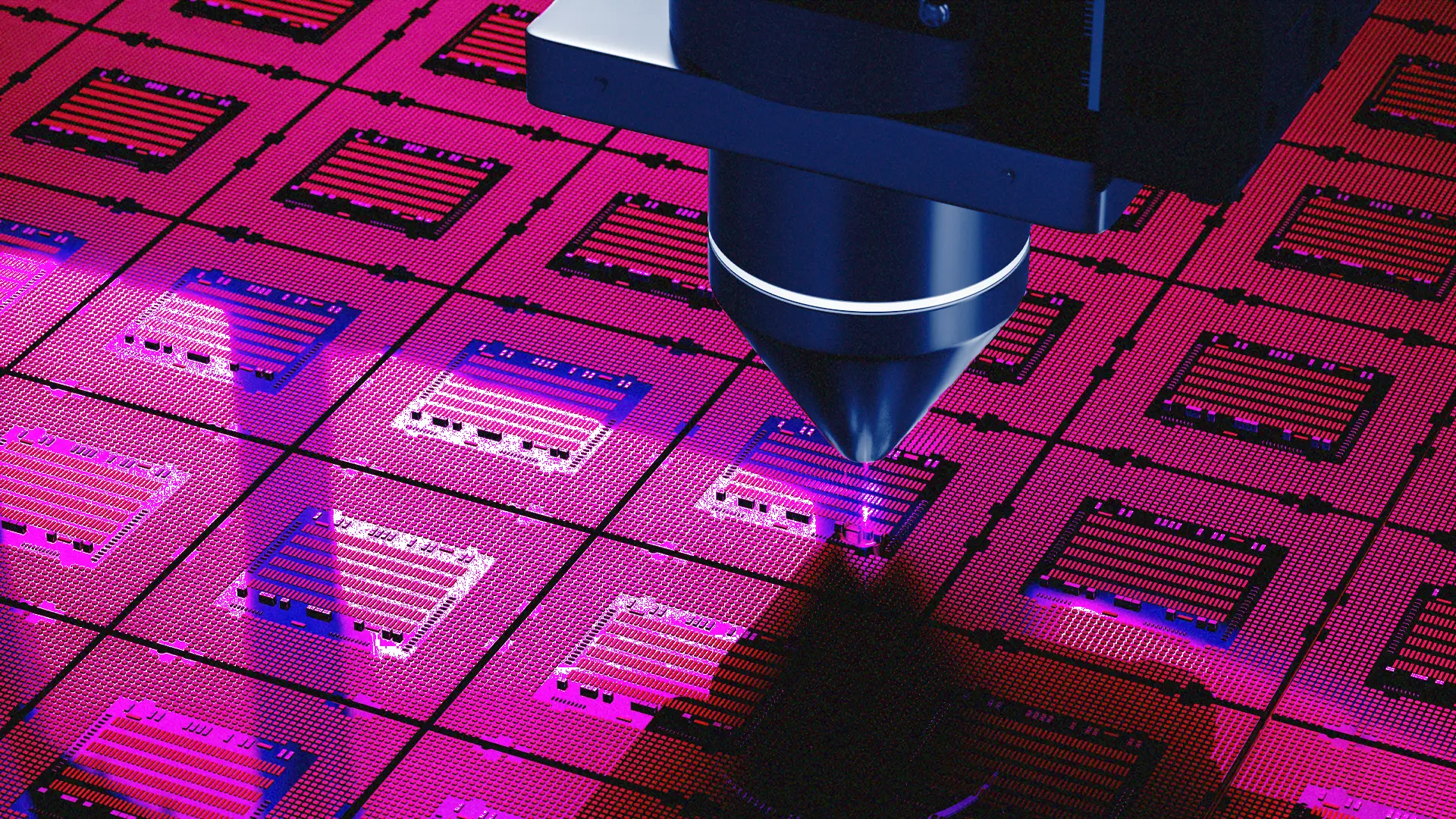

Sensible manufacturing makes use of interconnected, clever applied sciences to remodel conventional processes. It’s not about automating particular person duties—it’s about enabling complete programs to work collectively, sharing knowledge, and adapting in actual time. On this period, knowledge is the brand new oil, and the flexibility to behave on it’s the key to driving innovation.

This marks a serious shift from earlier industrial fashions. The place conventional factories relied on guide labor or standalone automation, good factories embrace full digital integration. Machines, sensors, and management programs join throughout the operation to drive transparency, agility, and optimization. The outcome: factories which might be predictive, adaptable, and designed for resilience.

Core applied sciences powering good manufacturing

AI and machine studying

AI is the mind behind good manufacturing. It delivers real-time insights, automates advanced choices, and makes effectivity beneficial properties that guide processes merely can’t. Predictive upkeep permits programs to detect and handle gear points earlier than failures occur, decreasing downtime and saving cash. Laptop imaginative and prescient and anomaly detection are used for automated high quality management, making certain constant requirements and decreasing waste. AI additionally optimizes scheduling, stock, and useful resource allocation for smoother manufacturing flows.

Industrial Web of Issues (IIoT)

The IIoT connects each system on the manufacturing facility flooring. Sensible sensors and machines generate fixed streams of knowledge, fueling every thing from predictive analytics to autonomous decision-making. This allows machine-to-machine communication and responsive management programs. IIoT additionally enhances power effectivity, identifies course of bottlenecks, and optimizes stock administration—all in actual time.

Digital twins

A digital twin is a digital mannequin of a bodily system. It permits producers to simulate and check every thing—from new product designs to sustainability methods—earlier than implementing them. Digital twins are used to optimize manufacturing facility layouts, enhance power utilization, and predict upkeep wants. Whereas the upfront funding could be excessive, the long-term advantages in effectivity, uptime, and innovation are important.

Robotics

In the present day’s robotics go far past repetitive duties. Enhanced by AI, fashionable robots can deal with advanced features with velocity and precision. They’re serving to to shut crucial labor gaps, particularly for hazardous or bodily demanding roles. By adaptive studying, robots repeatedly enhance their efficiency and may function collaboratively with human staff. This hybrid workforce is already reshaping manufacturing traces throughout sectors.

Constructing an interconnected good manufacturing ecosystem

Digital transformation occurs when these applied sciences work collectively. By integrating AI, IIoT, digital twins, and robotics, producers can create a very clever ecosystem. Information flows seamlessly throughout programs, enabling real-time changes and predictive choices.

Cloud and edge computing play key roles on this transformation. Edge units course of knowledge regionally on the machine stage for fast motion, whereas cloud platforms present the big-picture view for strategic evaluation and system-wide coordination. Suppliers like Microsoft Azure and Siemens supply complete platforms that combine analytics, digital simulation, fault detection, and predictive modeling—multi function suite.

However transformation isn’t solely technical—it’s human. Implementing good manufacturing requires technical experience, retraining, and sometimes exterior help. It’s as a lot an organizational shift as it’s a technological one.

The way forward for good manufacturing

Sensible manufacturing is rapidly evolving towards hyper-automation—factories that may monitor, optimize, and even right themselves with little human enter. These extremely smart programs help extra sustainable operations by chopping power use, minimizing waste, and enabling round economic system practices. The environmental and financial implications are important.

We’re additionally approaching a future the place humanoid robots might tackle extra bodily labor. As NVIDIA CEO Jensen Huang lately famous, “Humanoid robots are lower than 5 years away from seeing large use in manufacturing services.” This shift prompts deeper questions concerning the evolving position of people in industrial work.

As machines tackle repetitive duties, human staff will shift towards roles that prioritize creativity, problem-solving, and innovation. However that requires new abilities—knowledge literacy, robotics fluency, and programs pondering. Organizations that put money into coaching at this time would be the ones thriving tomorrow.

Case examine: Rockwell

Rockwell Automation, in collaboration with Aquent, developed a digital twin of a bodily meeting line at their Milwaukee company customer heart to showcase the manufacturing facility of the long run to potential prospects. Dealing with challenges in creating real-time 3D graphics and interactive code, Rockwell Automation partnered with Aquent Studios to deliver this immersive venture to life.

Inside a three-month timeframe, Aquent Studios’ UX Designers crafted an intuitive touchscreen interface, simplifying advanced ideas for guests of all ages. The group transformed CAD meeting line knowledge into real-time mesh knowledge utilizing the Unity sport engine, making certain synchronization between the bodily and digital meeting traces primarily based on stay or simulated knowledge. This collaboration successfully bridged the hole between bodily manufacturing processes and digital visualization, offering an interactive and academic expertise for guests.

Conclusion

Sensible manufacturing is already reshaping how we construct, produce, and compete in international markets. For American business, it affords an opportunity to deal with long-standing challenges—whereas positioning to take care of our international management in lots of industries.

However this revolution requires greater than instruments. It calls for imaginative and prescient, funding, and dedication—from executives and engineers to frontline staff and tech innovators. The producers who act now—adopting interconnected programs, investing in folks, and pondering long run—would be the ones who thrive within the subsequent period of American business.

The longer term isn’t automated. It’s good.