Preventive upkeep packages are important for retaining services protected, environment friendly, and compliant. However even essentially the most skilled upkeep groups face challenges when data is fragmented throughout departments. Conventional handbook strategies like paper logs, spreadsheets, and disconnected methods make it troublesome to coordinate with procurement, stock, compliance, and finance groups.

A contemporary facility administration system offers groups the flexibility to automate duties, share real-time knowledge, and collaborate throughout departments. When everybody works from the identical supply of fact, preventive upkeep turns into extra proactive, strategic, and resilient.

Key takeaways

- Collaboration throughout departments ensures that everybody works from the identical supply of fact, decreasing gaps in communication that may result in missed inspections, delayed repairs, and price range shortfalls

- Sharing knowledge between upkeep, finance, procurement, and compliance groups allows knowledgeable choices about preventive upkeep, budgeting, and useful resource allocation

- Centralized knowledge and automatic recordkeeping assist organizations keep compliant with regulatory necessities, scale back downtime, and enhance total facility efficiency

Gaps in communication typically result in missed inspections, delayed repairs, and price range shortfalls. Upkeep groups might battle to justify replacements, observe half availability, or present documentation throughout audits, not as a result of the work isn’t being executed, however as a result of the information isn’t centralized or accessible.

Loop in finance to point out the worth of preventive upkeep

When upkeep and finance groups function in silos, preventive upkeep packages endure. With out shared knowledge, finance might not perceive the urgency behind sure repairs or the long-term worth of preventive work. That disconnect can result in underfunded budgets, delayed replacements, and a reactive upkeep cycle that finally ends up costing you extra.

A contemporary preventive upkeep administration system helps bridge that hole by:

- Evaluating prices of preventive vs. reactive upkeep

- Highlighting financial savings from prevented breakdowns

- Forecasting price range wants based mostly on asset efficiency

- Monitoring asset lifecycle prices to help capital planning

By sharing this knowledge with finance, you assist them see the complete image—not simply the price of upkeep, however the worth it delivers.

How upkeep knowledge helps finance plan for preventive and capital spend

Your workforce completes quarterly service on backup turbines, decreasing emergency repairs. You generate a report out of your PM system displaying the service historical past, price financial savings, and prolonged asset lifespan. Finance then makes use of this knowledge to approve a price range enhance for subsequent yr’s preventive upkeep program.

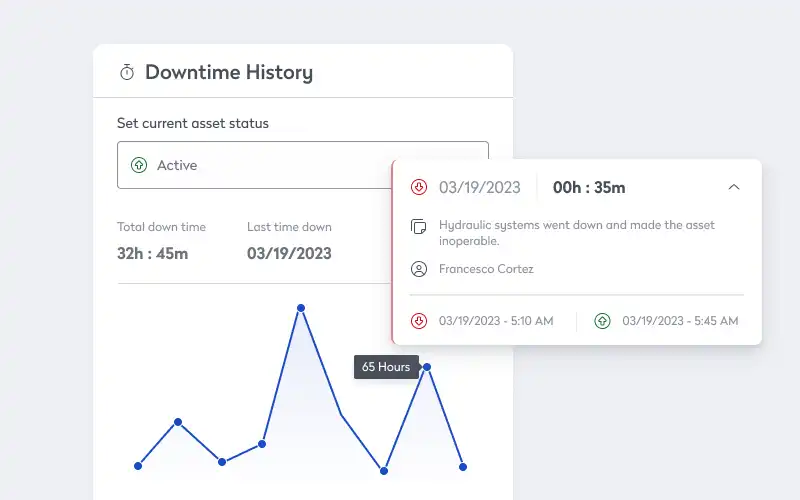

You additionally discover that a number of rooftop HVAC items are nearing end-of-life and have required frequent repairs. Utilizing your system, you compile a report displaying complete restore prices, downtime affect, and projected failure threat. Finance makes use of this knowledge to develop a capital enchancment plan that features changing the items over the subsequent two quarters earlier than they fail throughout peak season.

Coordinate with the procurement workforce to enhance provider choices

Stock points can derail even one of the best preventive upkeep plans. If elements aren’t obtainable if you want them, scheduled upkeep turns into reactive firefighting. And when suppliers ship late, ship incorrect objects, or fail to satisfy high quality requirements, your workforce pays the worth in downtime and frustration.

These issues typically stem from a scarcity of visibility. Upkeep groups know which elements are used most frequently and which suppliers trigger delays, however stock and buying groups might not have entry to that knowledge.

A contemporary preventive upkeep administration system helps shut that hole by:

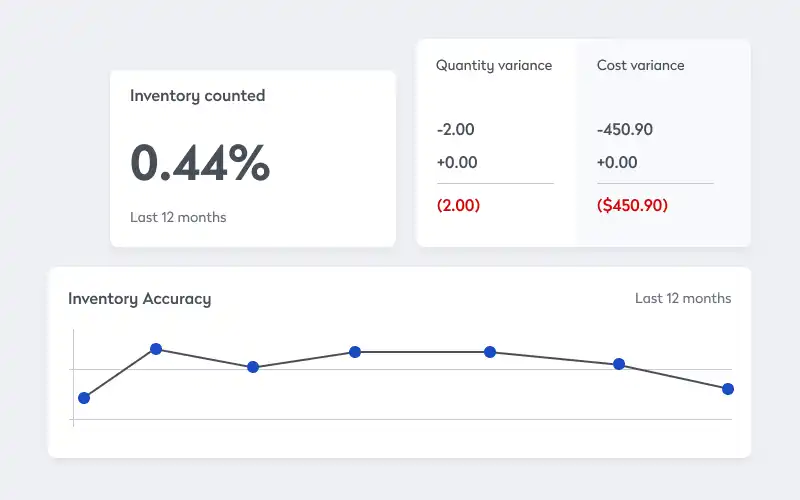

- Monitoring half utilization by asset, location, and frequency

- Logging provider supply occasions, accuracy, and achievement charges

- Setting minimal inventory thresholds for high-use or essential objects

It additionally helps you flag elements that regularly trigger delays or require rush orders.

Utilizing PM knowledge to strengthen provider relationships

Your workforce regularly replaces belts on a conveyor system, however the half is usually out of inventory. You employ your system to point out that the belt is used month-to-month throughout three places and that one provider has a 40% late supply charge. The procurement workforce makes use of this knowledge to change to a extra dependable provider and enhance inventory ranges, decreasing delays and bettering uptime.

You additionally discover {that a} particular kind of filter utilized in HVAC methods is usually changed throughout seasonal PM duties. Your system reveals that utilization spikes in spring and fall, however stock ranges stay flat year-round. You share the development with the stock workforce, who alter ordering schedules to match seasonal demand. The consequence: fewer delays, higher air high quality, and smoother PM execution.

Accomplice with compliance to automate recordkeeping, keep audit-ready

Preventive upkeep packages play a essential position in assembly regulatory necessities. When compliance groups depend on handbook logs or disconnected methods, although, it’s straightforward for data to fall by means of the cracks.

Missed documentation, late inspections, or incomplete experiences can result in fines, failed audits, and even security dangers.

A contemporary facility administration system helps you keep forward by:

- Robotically producing work orders for scheduled PM duties

- Capturing technician notes, timestamps, and asset historical past

- Creating audit-ready experiences which can be searchable and exportable

- Centralizing documentation for straightforward entry throughout departments

Automation helps compliance throughout industries, the place rules typically tie on to preventive upkeep.

Assembly business requirements with PM automation

In manufacturing and industrial settings, Occupational Security and Well being Administration (OSHA) requires employers to implement preventive upkeep procedures to manage office hazards.

For instance:

- Lockout/tagout procedures should be documented and adopted throughout gear servicing

- Machine guarding inspections should be logged to forestall damage

- Air flow methods should be maintained to manage publicity to airborne contaminants

Related companies exist in different nations, together with the Canadian Centre for Occupational Well being and Security, the UK’s Well being and Security Govt, Protected Work Australia, Germany’s Federal Institute for Occupational Security and Well being, and Japan’s Ministry of Well being, Labour and Welfare.

Utilizing the PM system, you’ll be able to schedule these inspections, log completion, and retailer data for audits. You scale back threat and guarantee your workforce meets regional security requirements.

In healthcare services, compliance is much more complicated. Hospitals and clinics in America for instance should meet requirements from a number of companies, together with:

So, your workforce completes month-to-month inspections of emergency lighting and hearth alarms in a hospital. Utilizing your PM system, you log every inspection with technician ID, timestamp, and consequence. When The Joint Fee arrives for a scheduled audit, the compliance workforce pulls a full report displaying that every one life security methods had been inspected on time and handed.

In a producing plant, your workforce performs quarterly inspections on conveyor methods. OSHA requires documentation of those inspections to make sure protected operation. Your system mechanically generates the work orders, logs technician notes, and shops the data. Throughout an OSHA go to, you present a full historical past of inspections and repairs, demonstrating compliance and avoiding penalties.

Work with procurement to make smarter repair-or-replace choices

Upkeep groups know which property break down repeatedly and which of them drain time and price range. Until procurement has entry to that knowledge, although, they could proceed investing in repairs when alternative could be cheaper.

With a contemporary facility administration system, you’ll be able to:

- Monitor restore frequency and value for every asset

- Generate experiences displaying complete spend over time

- Flag property approaching end-of-life based mostly on efficiency tendencies

By monitoring tendencies over time, you’ll be able to precisely decide the place an asset is in its life cycle.

Serving to procurement prioritize replacements with restore knowledge

Your workforce notices {that a} rooftop HVAC unit has required 5 emergency repairs previously yr. You pull a report out of your PM system displaying the unit’s restore historical past, downtime, and complete price. Procurement makes use of that knowledge to justify changing the unit in subsequent quarter’s capital price range.

Stronger collaboration helps procurement prioritize replacements based mostly on real-world upkeep knowledge, not simply age or producers’ suggestions.

Flip collaboration right into a aggressive benefit

Preventive upkeep doesn’t function in a vacuum. Its success is dependent upon the power of your connections throughout departments. When finance understands the price financial savings, stock groups anticipate half demand, compliance groups entry full data, and procurement makes data-driven alternative choices, your upkeep program turns into a strategic asset.

By leveraging a contemporary facility administration system to centralize knowledge and streamline communication, you empower each workforce to contribute to raised outcomes. The result’s fewer breakdowns, smarter spending, stronger compliance, and a facility that runs with confidence and readability.