Occupational Security and Well being Administration (OSHA) violations shortly develop into pricey. Fines for critical violations can attain $16,550, whereas willful or repeated violations can develop to $165,514 every. For facility managers, staying forward of compliance necessities means having clear visibility into security protocols, coaching data, and inspection schedules. Digital facility administration instruments make that potential by centralizing documentation and automating the workflows that assist safer, extra accountable operations.

Key takeaways

- OSHA fines are steep however preventable: Digital instruments assist facility managers keep forward of inspections and keep away from pricey violations by automating security checks and documentation

- Centralized data assist compliance: With digital facility administration software program, coaching certifications, inspection logs, and tools standing are all saved in a single place and simple to entry throughout audits

- Automated workflows cut back human error: Standardized checklists and recurring process scheduling be sure that important security procedures aren’t missed, even throughout busy shifts or throughout a number of places

OSHA units and enforces office security and well being requirements for each personal and public sector employers in the US. Along with enforcement, OSHA offers coaching, outreach, training, and help to assist organizations preserve secure working environments.

Understanding office security OSHA compliance

OSHA compliance officers conduct unannounced facility inspections to evaluate office security. Throughout an inspection, the officer sometimes meets with the ability supervisor and walks by means of the positioning to determine potential hazards. After the walkthrough, the officer holds a closing convention to debate findings.

If inspectors uncover violations, OSHA points a quotation that outlines the particular points, recommends corrective actions, and units deadlines for compliance.

OSHA fines differ relying on the sort and severity of the violation, they usually can add up quicky. A single critical violation can value greater than $16,000, whereas willful or repeated violations can attain over $165,000 every. If hazards go uncorrected, every day fines could apply, compounding the entire shortly. For corporations with a number of infractions or systemic security failures, penalties can escalate into the hundreds of thousands.

How a digital facility administration answer streamlines fall safety compliance

Falls stay the main explanation for fatalities within the development business, and OSHA’s fall safety customary 29 CFR 1926.501 continues to high the listing of most incessantly cited violations yr after yr. The regulation requires employers to supply fall safety programs for employees at elevations of six ft or extra in development, and 4 ft on the whole business.

Assign the best technician each time

Correct coaching is the muse of fall safety. Staying compliant with OSHA’s fall safety requirements, although, requires extra than simply checking a field. It calls for ongoing coordination throughout folks, tools, and processes.

A digital facility administration answer provides you the instruments to handle all of it in a single place, so that you’re not counting on reminiscence, spreadsheets, or disconnected programs.

You should use the software program to take care of a centralized document of each technician’s certification. When a brand new work order is available in, for instance for rooftop HVAC upkeep, you don’t should guess who’s certified. The system means that you can filter your crew primarily based on coaching data, so that you assign the job to somebody who’s licensed to work at peak and skilled in fall safety procedures.

As a result of you may robotically log the task together with a timestamp and hyperlink to the technician’s profile, you have got a transparent audit path if OSHA ever asks for documentation.

Connect security protocols and hyperlink PPE to each process

Earlier than the work begins, you utilize the platform to connect security protocols on to the work order. These embrace step-by-step directions for utilizing harnesses, anchors, and different fall safety gear. You additionally hyperlink the situation of the required PPE, which you’ve already cataloged within the system.

If the technician wants a particular kind of harness or gloves, they will examine the stock in actual time and see precisely the place to search out it, whether or not it’s in a storage room or a satellite tv for pc facility.

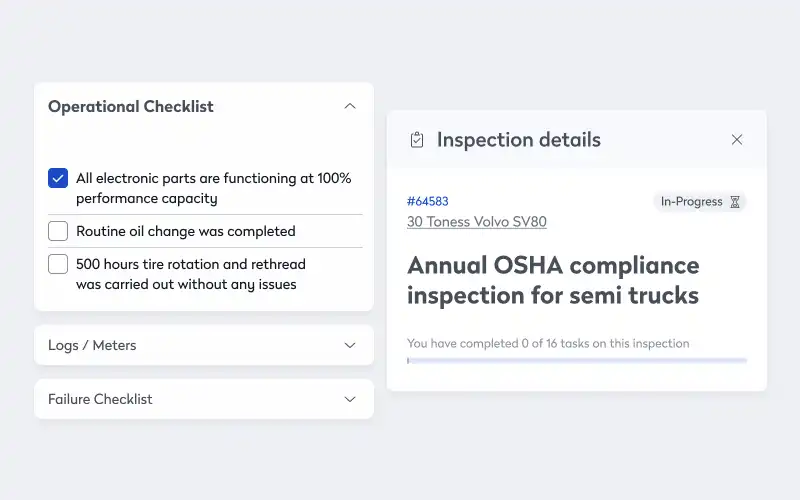

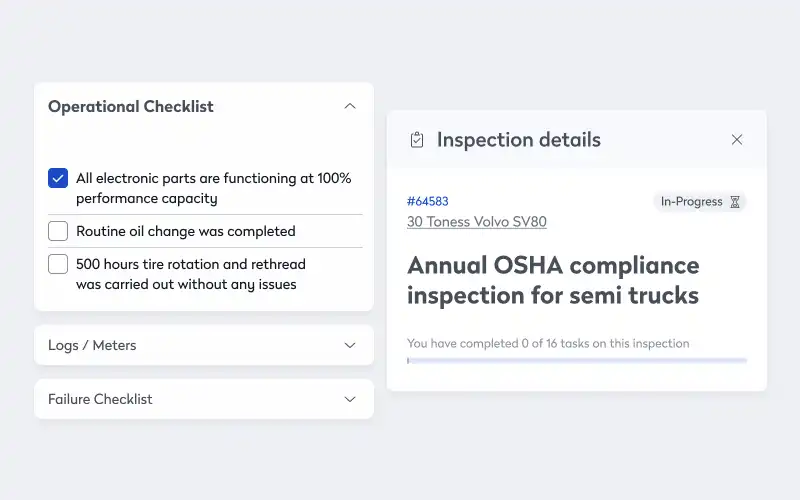

Automate digital security audits and preventive upkeep checklists

You can too construct preventive upkeep schedules into the system to make sure that fall safety tools is inspected usually. Anchors, harnesses, and lanyards are all tagged with inspection intervals, and you may set the software program to robotically generate recurring duties to your crew. The crew doesn’t miss any of the inspections, even throughout busy intervals or shift adjustments.

The system additionally helps standardize how inspections are carried out, so your crew follows the identical guidelines each time, lowering the danger of human error and making certain compliance with security rules. You’ll be able to observe completion charges, flag overdue duties, and generate studies for inner opinions or exterior audits.

When the crew flags a bit of drugs for substitute after an inspection, the system alerts you earlier than it’s assigned to a job, so that you’re by no means caught off guard by expired or broken tools, and you may act shortly to maintain your crew secure and your tasks on schedule.

How a digital facility administration answer helps hazard communication compliance

Hazard communication customary 29 CFR 1910.1200 ensures employees perceive the chemical substances they will encounter on the job. Employers are required to take care of correct security information sheets, correctly label containers, and supply coaching on chemical dangers and secure dealing with procedures.

Observe worker coaching and certification for chemical security

OSHA’s hazard communication customary requires that staff are skilled to know chemical hazards and know methods to shield themselves. A digital facility administration answer helps you meet this requirement by storing detailed coaching data for every worker.

You’ll be able to set automated reminders for retraining intervals and generate studies that present which staff are cleared to deal with particular substances. When assigning work orders, the system can filter your crew primarily based on coaching standing, making certain you select solely certified personnel, enhancing security.

Standardize labeling and documentation workflows

Correct labeling is a cornerstone of hazard communication, and a digital answer helps you implement consistency throughout your group. You’ll be able to create templates for chemical labels that meet OSHA’s necessities, together with sign phrases and hazard statements.

The system additionally helps documentation workflows for chemical dealing with procedures. For instance, you may require technicians to finish a guidelines earlier than utilizing a hazardous substance, verify PPE utilization, and log any incidents or spills. All of this information is saved in a single place, providing you with full visibility into how chemical substances are managed and used throughout your services.

How a digital facility administration helps machine guarding compliance

Machine guarding customary 29 CFR 1910.212 helps forestall accidents by mandating equipment have acceptable guards to guard operators and close by employees from pinch factors, rotating elements, and flying particles. Violations usually contain lacking or insufficient guards, particularly on older tools or throughout upkeep duties.

Schedule and doc guard inspections throughout all belongings

Machine guarding compliance is about putting in bodily obstacles after which sustaining them. A digital facility administration answer means that you can schedule recurring inspections for each machine that requires guarding, from conveyor belts and presses to mixers and cutters. You’ll be able to set inspection intervals primarily based on producer suggestions, utilization frequency, or inner security insurance policies.

Every inspection process can embrace detailed directions, images of correct guard placement, and fields for technicians to log findings. If a guard is lacking, broken, or improperly put in, the system permits the technician to flag the difficulty instantly and set off a corrective work order, making a closed-loop course of that ensures issues are addressed shortly and documented totally.

You can too generate studies displaying inspection historical past, compliance charges, and excellent points, that are beneficial information for inner audits or OSHA inspections.

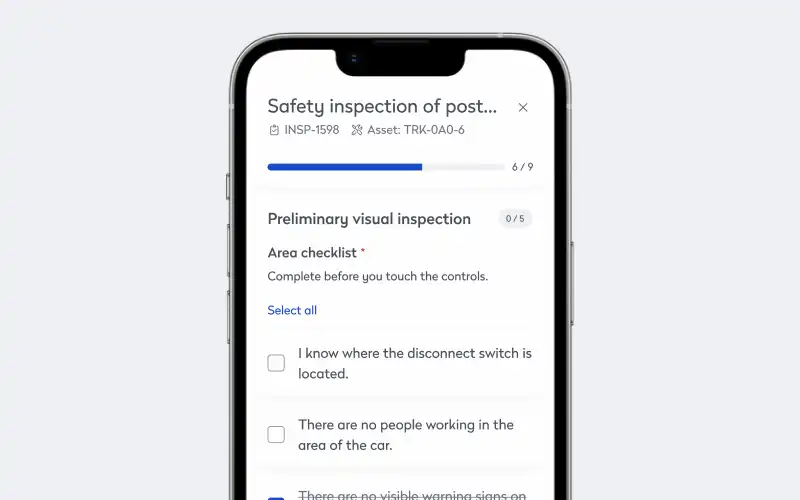

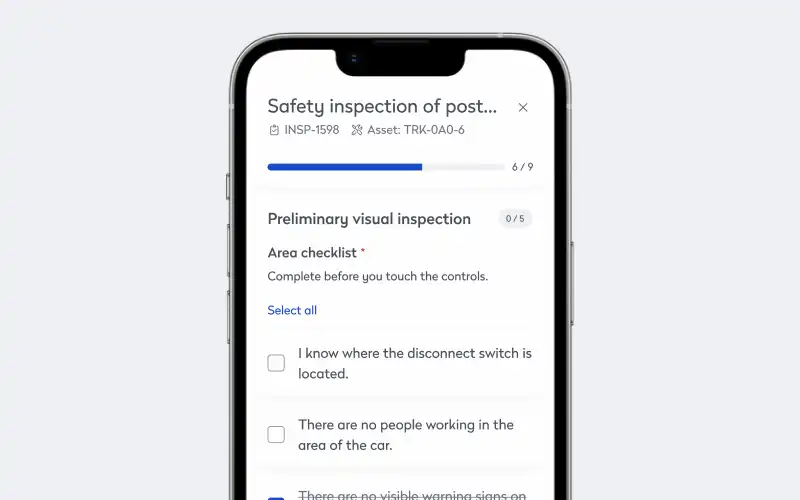

Embrace security checks with work orders for real-time accountability

When assigning work involving equipment, you may embed security protocols instantly into the work order, together with pre-use checklists that immediate technicians to confirm guard placement, check emergency stops, and ensure that no bypasses are in place. The technician should full these checks earlier than marking the duty as began, making a timestamped document of compliance.

The workflow ensures that security isn’t handled as an afterthought. If a technician identifies a hazard, they will log it instantly, and the system can escalate the difficulty to a supervisor or security officer. Actual-time accountability helps forestall accidents and helps a proactive security tradition.

Observe tools modifications and security upgrades over time

Machine configurations change over time, and holding observe of these adjustments is important for compliance. A digital facility administration answer means that you can doc each modification made to a machine, together with guard installations, management upgrades, and security retrofits. You’ll be able to log who carried out the work, when it was accomplished, and what requirements had been adopted.

The historic document helps you exhibit that your machines meet present security necessities and that you simply’ve taken steps to enhance safety over time. It additionally helps long-term planning by figuring out which machines may have future upgrades or substitute attributable to evolving security requirements.

Digital security instruments assist groups keep OSHA prepared

OSHA compliance is complicated, however digital facility administration instruments simplify the method. By automating inspections, monitoring certifications, and standardizing security protocols, facility groups can cut back threat, reply quicker to points, and preserve a transparent document of accountability. It’s not nearly avoiding fines. By embracing digital transformation, you may assist construct a safer, extra resilient office.