Upkeep departments play a crucial position in making certain operational continuity, security, and asset reliability throughout services. Even extremely expert groups, nevertheless, face challenges when communication is fragmented or inconsistent. Computerized upkeep administration methods (CMMS) could be instrumental in serving to organizations construct a tradition of collaboration that then strikes them away from reactive, siloed workflows towards coordinated, data-driven upkeep operations.

Key takeaways

- A CMMS supplies clear communication and shared visibility, decreasing missed duties and duplicate efforts by making certain technicians and supervisors have entry to the identical real-time knowledge

- By enabling real-time updates and centralized visibility into energetic work orders, a CMMS helps eradicate delays in communication, particularly throughout shifts, thereby minimizing disruptions and defending asset integrity

- A CMMS helps efficient upkeep planning by offering insights into technician availability, ability units, and historic efficiency, and preserves institutional information by appearing as a centralized repository for work order historical past and determination particulars

With out shared visibility and powerful communication, even routine upkeep can rapidly change into an costly guessing sport. With the fitting mixture of collaboration instruments, your upkeep groups can work collectively higher.

What are the challenges of siloed upkeep work?

Siloed upkeep operations usually lead to fragmented communication, duplicated efforts, and inconsistent activity execution. When technicians, supervisors, and planners lack entry to shared knowledge, routine actions change into disjointed, and effectivity and reliability undergo.

Technicians miss work orders, misunderstand priorities, and delay crucial updates, particularly when groups lack shared visibility throughout shifts or areas.

The shortage of coordination not solely impacts day-to-day effectivity but additionally undermines long-term planning and compliance. With no centralized system to trace efficiency, assign duty, and doc outcomes, groups battle to establish patterns, stop recurring points, and preserve accountability.

Over time, these gaps can result in elevated downtime, increased operational prices, and diminished confidence within the upkeep perform.

What are the long-term advantages of collaborative upkeep instruments?

Collaborative upkeep instruments convey quite a few advantages, together with improved coordination, sooner response occasions, and higher useful resource allocation, all of which will help groups transition from reactive to proactive upkeep operations.

Fewer missed duties, much less duplicate effort

Clear communication and shared visibility are foundational to efficient upkeep coordination. When technicians and supervisors function with entry to the identical real-time knowledge, it turns into considerably simpler to handle each day workloads with out overlap or confusion.

For instance, in a facility with out centralized activity monitoring, managers would possibly accidently dispatch two separate technicians to examine the identical HVAC unit, leading to wasted labor hours and delayed consideration to different priorities. A CMMS helps mitigate these kinds of oversights by offering a unified view of all energetic, scheduled, and accomplished work orders.

Supervisors can assign duties with confidence, and technicians can confirm assignments earlier than starting work.

Over time, higher coordination results in a measurable discount in overdue work orders and a noticeable enchancment in first-time repair charges. Upkeep groups spend much less time backtracking or redoing work and extra time executing duties that instantly help operational objectives.

Sooner response occasions

Well timed response to upkeep points is crucial to minimizing disruption and defending asset integrity. In lots of services, delays in communication, particularly throughout shifts, can lead to minor issues escalating into pricey failures. A CMMS helps the staff eradicate these delays by enabling real-time updates and centralized visibility into energetic work orders.

Think about a situation the place a leak is reported in the course of the night time shift. With no shared system, the morning crew may not obtain the data till hours later, delaying the response and rising the chance of water harm.

With a CMMS in place, the staff can log the problem instantly, so the subsequent shift can entry the main points as quickly as they start work.

The upper degree of responsiveness instantly impacts key metrics, together with:

- Imply Time to Restore (MTTR): By streamlining communication and making certain technicians have instant entry to problem particulars, CMMS platforms assist groups scale back the time it takes to diagnose and resolve issues

- Imply Time Between Failures (MTBF): Sooner interventions stop small points from compounding, which helps prolong the operational life of apparatus and scale back the frequency of breakdowns

- Work Order Response Time: CMMS platforms assist groups automate notifications and allow cell entry. A technician can obtain and settle for duties instantly from their system, eliminating delays brought on by guide dispatching or paper-based methods

Improved response occasions are usually not nearly velocity. They’re about precision, coordination, and the flexibility to behave instantly on correct data.

Improved planning and useful resource allocation

Efficient upkeep planning is dependent upon extra than simply assigning duties. It requires a transparent understanding of technician availability, ability units, and historic efficiency. With out entry to this knowledge, supervisors usually depend on assumptions or guide monitoring, which may result in uneven workloads, underutilized sources, and missed alternatives for optimization.

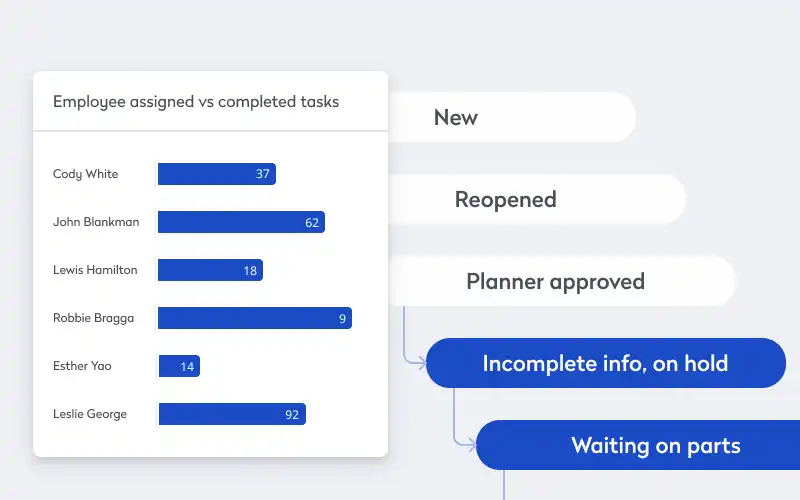

A CMMS supplies the division with visibility into technician schedules, activity completion charges, and time-on-task metrics, permitting supervisors to make knowledgeable selections about staffing and activity distribution.

For instance, if one technician constantly completes work orders effectively and with minimal follow-up, they might be higher fitted to advanced or time-sensitive assignments. Figuring out technicians who require extra help or coaching turns into simpler when efficiency knowledge is centralized and accessible.

These insights help stronger labor utilization charges, making certain that accessible sources are matched to precise operational wants. It additionally contributes to extra constant preventive upkeep compliance, as supervisors can plan recurring duties round technician capability slightly than reacting to last-minute availability gaps.

Over time, there’s a extra balanced workload, fewer scheduling conflicts, and improved total effectivity throughout the upkeep staff.

Constant information switch

In lots of upkeep departments, crucial operational information lives within the heads of skilled technicians. When these people retire, change roles, or are unavailable, that information could be misplaced, leading to longer decision occasions, repeated errors, and elevated downtime.

Leveraging a CMMS, managers can protect institutional information by appearing as a centralized repository for work order historical past, technician notes, photographs, and determination particulars. When a technician paperwork how they resolved a recurring problem with a selected asset, that data turns into a part of the system’s document.

New hires or much less skilled staff members can then reference these entries to grasp previous approaches, keep away from frequent pitfalls, and construct confidence of their decision-making.

Structured information switch reduces the influence of turnover and helps smoother onboarding. It additionally helps standardize upkeep practices throughout shifts and areas, making certain that groups function with constant expectations and entry to the identical data.

In the long run, it strengthens the division’s resilience and reduces the chance of downtime brought on by gaps in expertise or communication.

What are among the key CMMS options that help teamwork?

Key CMMS options that help teamwork embody upkeep historical past documentation, workload balancing instruments, cell entry, and task-level commenting.

Collectively, they assist create a centralized platform for real-time collaboration and constant practices.

Upkeep historical past and asset-level documentation

Groups depend on upkeep historical past and asset-level documentation to protect institutional information and help constant requirements. Each activity the staff performs on an asset goes into the document, together with technician notes, decision steps, and supporting documentation.

When technicians encounter recurring points, they’ll evaluate how related issues have been resolved previously, serving to them make knowledgeable selections and keep away from repeating ineffective options.

New technicians use this documentation to be taught from earlier work, whereas skilled staff members reference previous repairs to establish patterns or root causes.

By sustaining a shared archive of data, groups scale back downtime brought on by gaps in expertise and strengthen total efficiency.

Technician workload balancing and task instruments

Supervisors use workload balancing instruments to assign duties based mostly on technician availability, ability units, and present workload. As a substitute of counting on guide scheduling or assumptions, they’ll view real-time knowledge to distribute assignments pretty and effectively, serving to stop overloading sure staff members and ensures that specialised duties go to technicians with the fitting expertise.

When a technician has a powerful monitor document with a selected asset sort, supervisors can prioritize them for associated work.

Over time, this results in extra balanced workloads, improved morale, and better activity completion charges.

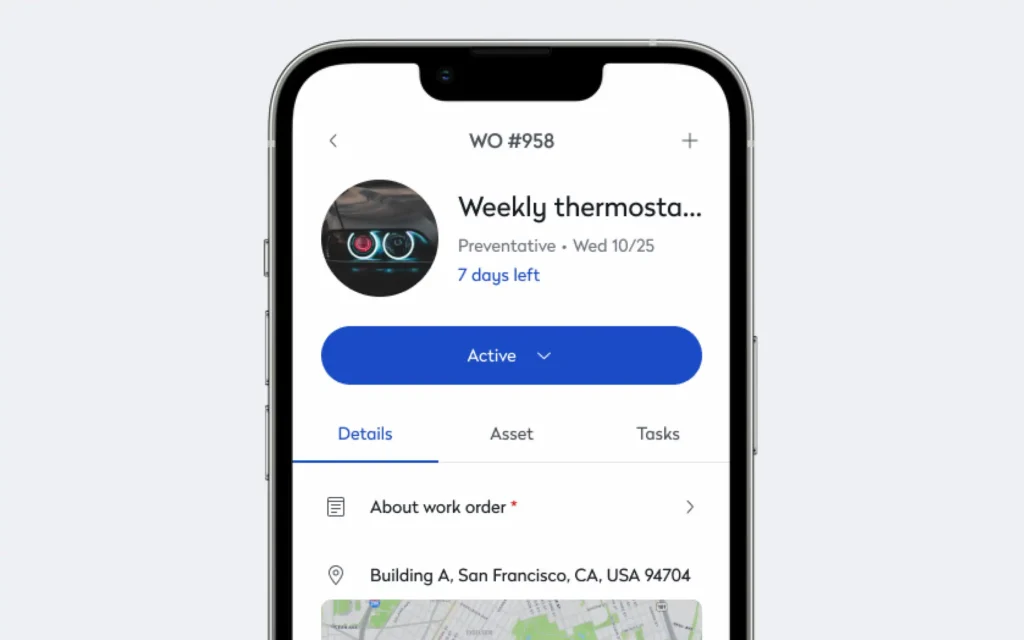

Cellular work order entry and updates

Technicians use cell entry to work together with the CMMS instantly from the sphere. They obtain assignments, replace activity statuses, add photographs, and doc work with out returning to a central workstation, which is very priceless in giant services or multi-building campuses, the place journey time between areas can decelerate communication and delay activity completion.

For instance, a technician repairing a rooftop HVAC unit can shut out the duty and flag follow-up wants instantly, permitting the subsequent shift to proceed with out interruption.

Supervisors additionally profit from cell visibility, utilizing real-time updates to regulate priorities and reply to altering circumstances extra successfully.

Job-level commenting and collaboration threads

Technicians and supervisors use task-level commenting to speak instantly inside particular person work orders, permitting them to ask questions, share updates, and make clear directions in context, eliminating the necessity for exterior emails or verbal updates that may be misplaced or misunderstood.

The characteristic is very helpful for multi-step repairs or inspections that span a number of shifts. A technician who begins troubleshooting a posh fault can go away detailed notes and suggestions for the subsequent technician, who can then evaluate the complete historical past earlier than persevering with.

Improved continuity, reduces guesswork, and ensures everybody concerned has entry to the identical data.

Constructing a tradition of collaborative with CMMS

Collaboration in upkeep comes right down to making a shared framework the place groups can plan, execute, and be taught collectively. When managers use CMMS instruments to align assignments, technicians use cell entry to remain related within the discipline, and supervisors depend on historic knowledge to information selections, the result’s a extra coordinated, accountable, and resilient upkeep operation.

Constructing this tradition takes intention. It requires management to prioritize transparency, groups to undertake constant documentation practices, and everybody to interact with the system as a central supply of fact. Over time, these habits strengthen belief, scale back inefficiencies, and help steady enchancment.