Communication breakdowns, inconsistent processes, and delayed responses from throughout websites can rapidly escalate into pricey disruptions. When facility administration groups have to work throughout cities and even international locations, staying aligned requires extra than simply e-mail chains and spreadsheets.

A contemporary facility administration answer delivers the important thing options that make it easier to bridge gaps, bringing clear collaboration to advanced operations.

Key takeaways

- Fashionable facility administration options present a single, cloud-based platform the place all places feed into one supply of fact, eliminating guide knowledge assortment, guaranteeing everybody works from the identical data

- Options like real-time work order administration, built-in service request methods, and stock and asset monitoring instruments assist facility groups collaborate successfully throughout a number of places by offering visibility into work orders, requests, and asset upkeep histories, lowering delays and enhancing productiveness

- Analytics dashboards consolidate knowledge from all places into clear, actionable stories, so facility managers can monitor KPIs, establish developments, benchmark efficiency, and export stories for management and compliance critiques, making knowledgeable selections simpler

By understanding the core challenges and options offered, organizations can higher navigate the complexities of multi-site administration and enhance total collaboration.

Shut the gaps: Centralized entry for clearer visibility and sooner motion

Facility managers working throughout a number of places usually face the identical core problem of fragmented knowledge. Whether or not it’s chasing updates or reconciling stories, the dearth of a unified system slows down selections and creates blind spots.

For instance, a regional facility supervisor overseeing 5 websites spent hours every week chasing updates from native groups. Every location used its personal spreadsheet, and by the point knowledge was compiled, it was already outdated. The guide course of created blind spots and slowed down decision-making.

At one other firm, the company FM struggled to arrange month-to-month stories for management. Every web site submitted knowledge in several codecs, and reconciling the numbers took days. The dearth of standardization made it laborious to identify developments or justify finances requests.

One platform, one supply of fact for each location and each crew

A contemporary facility administration answer provides a single, cloud-based platform the place all places feed into one supply of fact, eliminating guide knowledge assortment and ensures that everybody, from technicians to executives, is working from the identical data.

With centralized entry, you possibly can:

- View real-time updates from each location

- Standardize knowledge codecs and reporting processes

- Set role-based permissions to manage who sees what

- Entry dashboards from any gadget, wherever

So, again on the regional firm, the FM now logs right into a dashboard that reveals stay knowledge from all 5 websites. They’ll spot developments, flag points, and share insights with management in minutes—not days. The time spent chasing updates is gone, changed by proactive planning and sooner responses.

On the different firm, the FM now not worries about month-to-month reporting. Every web site enters knowledge into the identical system, utilizing the identical format. The dashboard mechanically compiles the numbers, highlights anomalies, and generates charts that management can overview immediately. Funds conversations at the moment are backed by constant, credible knowledge.

Reply rapidly and confidently with real-time work order administration

Facility groups usually lose beneficial time after they attempt to monitor work orders manually. And not using a centralized system, requests slip by way of the cracks, updates are delayed, and visibility suffers, particularly throughout a number of places.

For instance, a technician at a distant warehouse flagged a damaged HVAC unit, however the request received buried in e-mail threads. The delay led to uncomfortable working situations and a drop in productiveness, whereas a upkeep supervisor at a multi-site retail chain struggled to trace open work orders. Some duties had been accomplished however by no means logged, whereas others had been forgotten totally.

With out visibility, it’s unimaginable to know what the crew has carried out and what they nonetheless have to do.

Actual-time work order instruments preserve groups aligned and points shifting ahead

Actual-time work order administration instruments assist your crew submit, monitor, and shut requests from cell units. You’ll be able to assign duties immediately and monitor progress throughout places, prioritizing duties based mostly on urgency and affect, and escalation workflows to make sure the crew is on high of important points. Standing updates are seen to all stakeholders, lowering the necessity for follow-up emails and cellphone calls.

With centralized work order administration, you possibly can:

- Submit and monitor requests from any location

- Assign duties immediately and monitor progress in actual time

- Prioritize points based mostly on urgency and enterprise affect

- Cut back delays with automated alerts and escalation workflows

Which means on the warehouse, the technician now submits the HVAC concern by way of an app. The supervisor sees it instantly, assigns it to the best particular person, and tracks the restore in actual time.

They repair it the identical day, and productiveness stays on monitor, whereas on the retail chain, the upkeep supervisor opens a dashboard exhibiting each open work order throughout all shops, and the crew can lastly deal with fixing issues as a substitute of chasing paperwork.

Give each worker a voice with an built-in service request system

Facility groups can’t repair what they don’t learn about, and when communication breaks throughout places, small points rapidly escalate.

And not using a constant technique to report issues, staff really feel unheard, and facility managers lose visibility into what’s occurring on the bottom.

For instance, staff at satellite tv for pc workplaces usually felt ignored when submitting upkeep requests. And not using a formal system, their emails had been straightforward to miss, and small points grew to become large issues.

In the meantime, at a producing firm, frontline staff had no clear technique to report facility points. They relied on verbal requests throughout shift adjustments, which had been usually forgotten or miscommunicated. The outcome was delayed repairs and rising frustration.

A unified request system improves communication and builds belief throughout groups

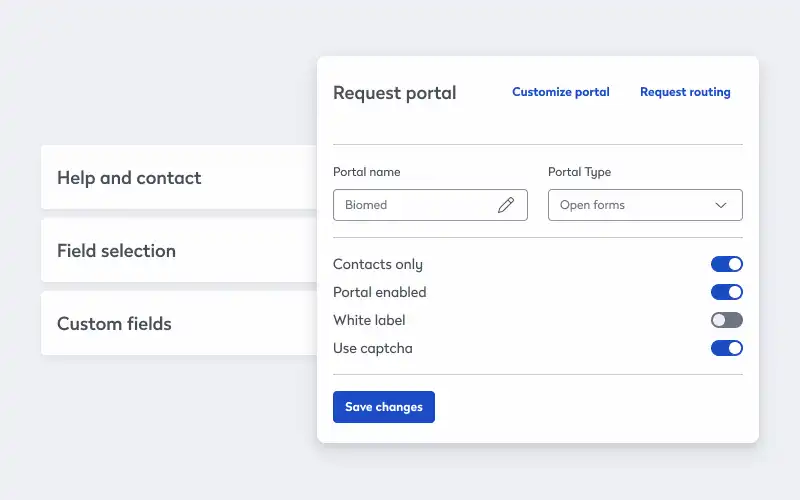

An built-in service request system provides everybody in your crew a easy, constant technique to report points. Requests are mechanically routed to the best crew and tracked by way of decision.

The interface is intuitive, permitting staff to submit requests from their telephones or desktops. Actual-time standing updates preserve everybody knowledgeable, and analytics assist facility managers establish recurring points and enhance service supply.

With a centralized request system, you possibly can:

- Give each worker a transparent technique to report points

- Route requests mechanically to the best crew

- Monitor progress and share real-time updates

- Use knowledge to establish patterns and enhance service

On the satellite tv for pc workplace, staff now use a cell app to submit requests. They obtain updates as the problem progresses, and the FM crew can spot patterns like recurring HVAC complaints and take proactive steps to enhance situations.

Within the manufacturing plant, staff submit requests immediately from the ground. The crew can use the system to log every concern, route it to the best technician, and monitor decision. Repairs occur sooner, and staff really feel heard and supported.

Cease losing sources with stock and asset visibility

Managing stock and property throughout a number of places is difficult, however with out shared visibility, it’s additionally inefficient. Duplicate orders, missed service home windows, and untimely replacements can all come from a scarcity of communication and coordination.

Think about a technician ordered a substitute half for a generator, unaware that the identical half was already stocked at a close-by location. In the meantime, a facility supervisor overseeing a number of campuses struggled to trace asset lifecycles. Tools was serviced inconsistently, and a few property had been changed prematurely just because their histories had been lacking.

Shared visibility helps groups coordinate stock and lengthen asset lifecycles

Stock and asset monitoring instruments present a unified view of components, gear, and utilization throughout all places. You’ll be able to see real-time stock ranges throughout websites, monitor upkeep histories and repair data, set alerts for low inventory or upcoming service wants, and keep away from pointless purchases and delays.

With shared stock knowledge, your technician sees that the wanted half is on the market at a close-by web site. They request a switch, full the restore the identical day, and keep away from pointless spending.

On the campus community, you now have full visibility into asset histories, capable of see which gear is due for service, which components are in inventory, and which property are nearing end-of-life. Lastly, you’re making data-backed selections.

Make assured, data-backed selections with cross-location analytics

Facility managers want greater than uncooked knowledge. They want insights. When data is scattered throughout methods and websites, it’s laborious to see the massive image and make knowledgeable selections.

Management requested for a quarterly report evaluating upkeep prices throughout areas. The ability crew scrambled to collect knowledge from completely different methods, resulting in inconsistent numbers and missed insights, whereas at one other group, the FM crew couldn’t clarify why vitality prices had been rising at one location. With out pattern knowledge or benchmarks, that they had no technique to examine or justify adjustments.

Analytics dashboards deliver readability and confidence to multi-site selections

Analytics dashboards consolidate knowledge from all places into clear, actionable stories. You’ll be able to monitor KPIs for upkeep, area, and asset efficiency, establish developments and recurring points throughout websites, benchmark efficiency to identify outliers and alternatives, and export stories for management and compliance critiques.

So, on the first firm, the FM crew now pulls up a dashboard that compares upkeep prices throughout areas in seconds. They establish which internet sites want consideration, suggest focused enhancements, and current clear knowledge to management.

On the second group, the FM crew makes use of vitality knowledge to pinpoint the supply of the associated fee enhance. They establish an outdated HVAC system, suggest a substitute, and again it up with efficiency benchmarks from different websites.

How ACE Recycling & Disposal improved cross-site collaboration with smarter facility instruments

ACE Recycling & Disposal, the most important impartial waste hauler within the western United States, operates throughout 18 places and manages greater than $10 million in stock and over 550 property.

Earlier than adopting a contemporary facility administration answer, their crew confronted a sequence of operational challenges that made it troublesome to remain aligned throughout websites. They relied on guide monitoring for stock and property, which led to accuracy charges as little as 30–45%. With out centralized knowledge, compiling efficiency metrics was time-consuming and inconsistent, limiting their capability to safe funding or make strategic selections.

With the best know-how in place, ACE noticed measurable enhancements throughout the board. Stock accuracy jumped to 95%, due to centralized monitoring and real-time visibility. Their crew now processes 5,000 work orders and a pair of,000 preventive upkeep duties every month with streamlined workflows that span all 18 places.

The truth is, with standardized knowledge and automatic dashboards, ACE secured $2 million in grants.

ACE’s story reveals what’s attainable when facility managers have the instruments to attach places, automate processes, and make data-driven selections.

Learn the complete success story.